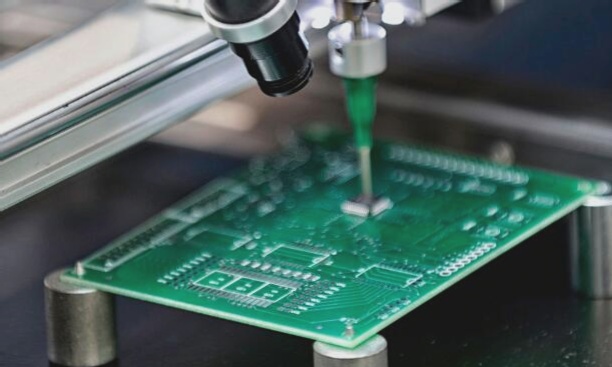

1. Aluminum PCB is a type of metal core printed circuit board, renowned for its exceptional heat dissipation capabilities and durability. It is widely regarded as the optimal choice for applications requiring efficient heat dissipation, as it facilitates the ideal dissipation of heat through its dielectric material, thereby ensuring the overall temperature stability of the project design. Below, we delve into the features, structure, and applications of Aluminum PCBs.

1. PCB aluminum-based copper clad laminate is a metal circuit board material composed of copper foil, a thermally conductive insulating layer, and a metal substrate. Its structure is divided into three layers:

① Circuit Layer: Equivalent to the copper clad laminate of an ordinary PCB, with a copper foil thickness ranging from 1oz to 10oz.

② Dielectric Layer: The insulation layer consists of a low thermal resistance thermally conductive insulating material. The thickness ranges from 0.003″ to 0.006″ inches and is a key design element of aluminum-based copper clad laminates, certified by UL.

③ Base Layer: This layer serves as a metal substrate, typically made of aluminum or copper. Aluminum-based copper clad laminate is distinct from traditional epoxy glass cloth laminate.

2. The PCB aluminum substrate comprises a circuit layer, a thermally conductive insulating layer, and a metal base layer. The circuit layer, usually etched copper foil, forms a printed circuit to connect various assembly components. Given its typical requirement for high current-carrying capacity, thicker copper foils ranging from 35μm to 280μm are preferred. The thermal insulation layer is pivotal in PCB aluminum substrate technology, often comprised of a special polymer filled with ceramics, boasting low thermal resistance, excellent viscoelasticity, thermal aging resistance, and resilience to mechanical and thermal stress.

3. T-101, T-111, T-112, T-113, T-114, as well as T-200, T-300, T-400, T-500, and T-600, among other high-performance PCB aluminum substrates, integrate thermally conductive and insulating layers. This technology endows them with exceptional thermal conductivity and robust electrical insulation. The metal base layer serves as the backbone of the aluminum substrate, necessitating high thermal conductivity, typically achieved with aluminum plates, though copper plates, offering superior thermal conductivity, are also viable options. These substrates are amenable to conventional machining techniques such as drilling, punching, and cutting. Compared to alternative materials, PCB materials offer unparalleled advantages, rendering them suitable for surface mount SMT public art of power components. They eliminate the need for radiators, significantly reducing volume, enhancing heat dissipation, and maintaining superior insulation and mechanical performance.

WellCircuits Limited specializes in multilayer Aluminum PCBs. For inquiries and quotes, please feel free to contact us at [email protected] anytime.

1. PCB aluminum-based copper clad laminate is a metal circuit board material composed of copper foil, a thermally conductive insulating layer, and a metal substrate. Its structure is divided into three layers:

① Circuit Layer: Equivalent to the copper clad laminate of an ordinary PCB, with a copper foil thickness ranging from 1oz to 10oz.

② Dielectric Layer: The insulation layer consists of a low thermal resistance thermally conductive insulating material. The thickness ranges from 0.003″ to 0.006″ inches and is a key design element of aluminum-based copper clad laminates, certified by UL.

③ Base Layer: This layer serves as a metal substrate, typically made of aluminum or copper. Aluminum-based copper clad laminate is distinct from traditional epoxy glass cloth laminate.

2. The PCB aluminum substrate comprises a circuit layer, a thermally conductive insulating layer, and a metal base layer. The circuit layer, usually etched copper foil, forms a printed circuit to connect various assembly components. Given its typical requirement for high current-carrying capacity, thicker copper foils ranging from 35μm to 280μm are preferred. The thermal insulation layer is pivotal in PCB aluminum substrate technology, often comprised of a special polymer filled with ceramics, boasting low thermal resistance, excellent viscoelasticity, thermal aging resistance, and resilience to mechanical and thermal stress.

3. T-101, T-111, T-112, T-113, T-114, as well as T-200, T-300, T-400, T-500, and T-600, among other high-performance PCB aluminum substrates, integrate thermally conductive and insulating layers. This technology endows them with exceptional thermal conductivity and robust electrical insulation. The metal base layer serves as the backbone of the aluminum substrate, necessitating high thermal conductivity, typically achieved with aluminum plates, though copper plates, offering superior thermal conductivity, are also viable options. These substrates are amenable to conventional machining techniques such as drilling, punching, and cutting. Compared to alternative materials, PCB materials offer unparalleled advantages, rendering them suitable for surface mount SMT public art of power components. They eliminate the need for radiators, significantly reducing volume, enhancing heat dissipation, and maintaining superior insulation and mechanical performance.

WellCircuits Limited specializes in multilayer Aluminum PCBs. For inquiries and quotes, please feel free to contact us at [email protected] anytime.