Surface Treatment Processes in PCB Manufacturing

- OSP (Organic Solderability Preservative):

- Gold Plating:

- ENEPIG (Electroless Nickel-Palladium Immersion Gold):

OSP acts as an insulating layer between copper and air, formed through a chemical reaction to create an organic film. It is cost-effective and preferred for large computer motherboards due to significant cost savings. However, OSP transparency poses challenges in visual inspection, and its non-conductive nature requires special testing procedures.

Gold plating, though costly, plays a crucial role in facilitating soldering and preventing corrosion on circuit boards. It is commonly used in memory stick gold fingers and connector springs, ensuring longevity and resistance to rust compared to other materials like copper and aluminum.

ENEPIG, featuring a palladium layer between nickel and gold, offers enhanced corrosion resistance during the replacement gold deposition process. This protective barrier prevents the substitution of nickel by gold, ensuring a reliable surface for immersion gold application.

Challenges and Benefits of Surface Treatment Processes

- OSP Challenges:

- Gold Plating Benefits:

OSP’s insulative nature requires additional steps for electrical testing and maintenance. Exposure to acid and temperature variations can affect soldering results, necessitating timely processing and reapplication if left exposed. Boards treated with OSP must be used promptly to retain effectiveness.

Gold plating not only aids in soldering and corrosion prevention but also maintains a lasting appearance over time. It is commonly found in mobile phone motherboards and immersion gold boards, offering superior durability compared to non-gold-plated alternatives.

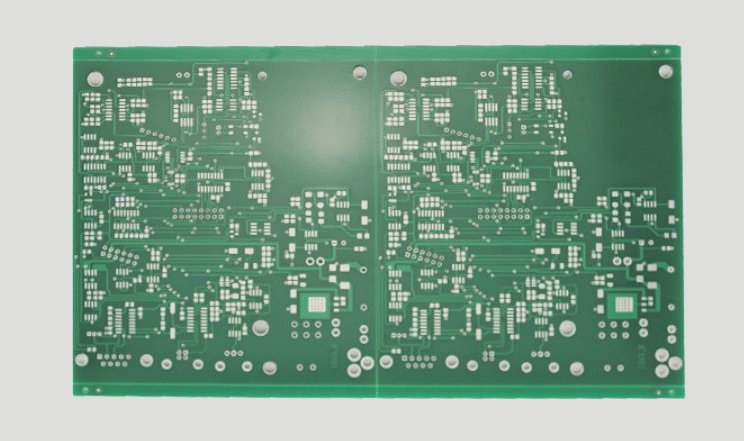

HASL (Hot Air Solder Leveling)

HASL, or hot air solder leveling, is a PCB surface coating process that involves applying molten tin-lead solder and using heated compressed air to create a protective layer that resists copper oxidation and ensures excellent solderability. This process forms a copper-tin metal compound at the solder-copper junction, typically with a thickness of 1 to 2 mils. While applying a tin layer aids in soldering, it does not offer the long-term reliability of gold. Over time, oxidation and corrosion may occur, particularly on pads exposed to air for extended periods, such as grounding pads and pin sockets. Despite its drawbacks, HASL is commonly used in small digital product circuit boards for its cost-effectiveness.

Surface Treatment Methods

1. Immersion Silver

The immersion silver process provides a simple and fast solution, offering a pure silver coating of 5~15μin thickness. Occasionally, organic materials are included to prevent silver corrosion and migration issues. Despite some loss of gloss over time, immersion silver maintains good electrical properties and solderability. However, without nickel beneath the silver layer, it lacks the physical strength of electroless nickel/immersion gold.

2. Immersion Tin

Immersion tin processes, compatible with various solder types, have historically faced reliability issues due to tin whisker formation and migration. To address these problems, organic additives have been introduced to create a granular tin layer, improving thermal stability and solderability.

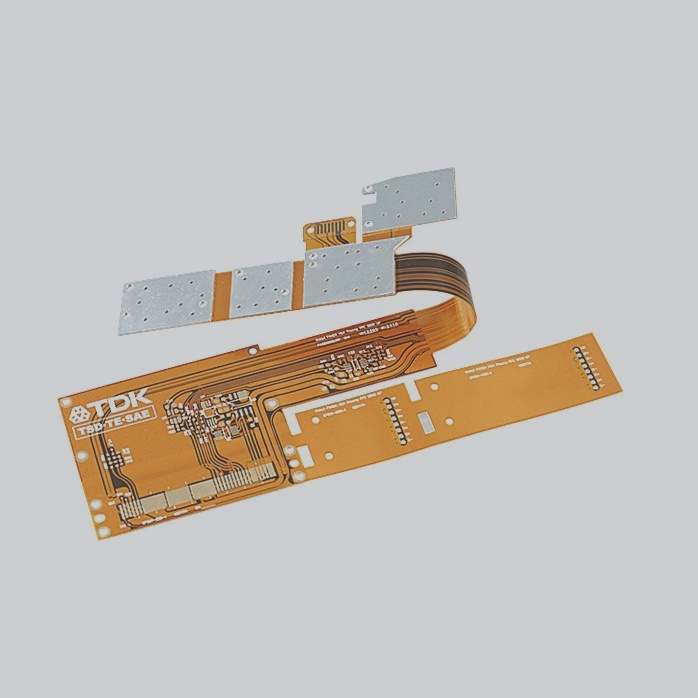

3. ENEPIG

ENEPIG is a versatile surface treatment method that can meet the demands of diverse assembly scenarios, offering unique characteristics and applications compared to other processes.