**Via:**

Once a via is chosen in the PCB design, it is essential to manage the spacing between it and adjacent elements. This is particularly important for the gaps between traces and vias, which can often be overlooked in the inner layers. If using automatic routing, you can select the “on” option in the Via Minimization submenu to automatically address this issue. The higher the required current-carrying capacity, the larger the vias need to be; for instance, larger vias are necessary for connecting power and ground layers to other layers.

**Silk Screen Layer:**

To aid in the installation and maintenance of the circuit, PCB design incorporates essential logos and text codes on both the top and bottom surfaces of the board. This includes component labels, nominal values, outline shapes, manufacturer logos, and production dates. Many beginners focus solely on the aesthetic arrangement of the text and symbols, often neglecting the practical implications on the PCB. As a result, characters may be obscured by components, encroach upon soldering areas, or overlap with adjacent components. Such design choices can complicate assembly and maintenance significantly. The guiding principle for arranging text on the silk screen layer is: “no ambiguity, clarity at a glance, and an appealing, professional appearance.”

**SMD Package:**

1. The Protel package library contains a wide array of SMD packages, which are surface-mounted devices. The most notable feature of these devices, besides their compact size, is the single-sided distribution of pin holes. Thus, when selecting such devices, it’s crucial to define their surface to prevent “missing pins.” Additionally, text annotations related to these components can only be placed along the component’s surface.

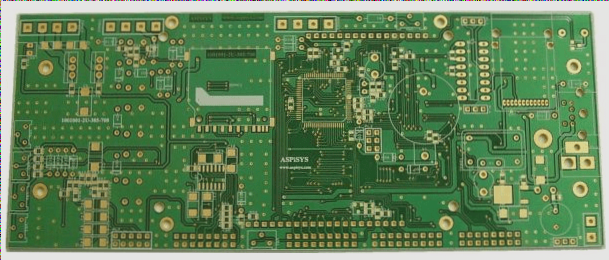

2. Filling Area:

The grid-like filled area (External Plane) and filled area (Fill) are named for their specific functions. The network-filled area processes a large copper foil section into a mesh, while the filled area retains the copper foil intact. Beginners often struggle to distinguish between the two during the design process; however, a close zoom reveals their differences. Because the distinction can be subtle, care must be taken when using either. The former effectively suppresses high-frequency interference, making it ideal for large shielded areas or high-current power lines. The latter is typically used in smaller areas, like general line ends or turn regions.

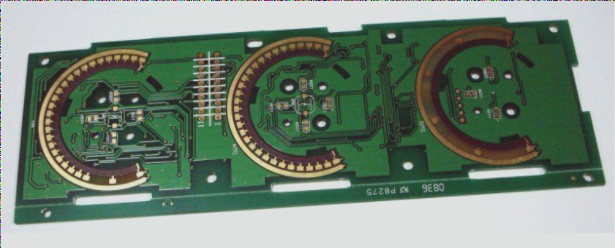

3. Pad:

The pad is one of the most crucial concepts in PCB design, yet beginners frequently overlook its selection and modification, often defaulting to circular pads. Choosing the appropriate pad type requires consideration of the component’s shape, size, layout, vibration, heating conditions, and force direction. Protel offers a variety of pad sizes and shapes in its library—such as round, square, and octagonal—but sometimes custom editing is necessary. For pads that generate heat or endure significant stress, a “teardrop shape” may be beneficial. In color TV PCB designs, many manufacturers adopt this approach.

4. Generally, the following principles should guide custom pad editing:

(1) When the pad’s length varies, the difference between the wire width and the pad’s side length should be minimal;

(2) Asymmetric pads are often needed when routing between component lead angles;

(3) Each component pad hole size should be tailored to the component pin thickness, ideally 0.2 to 0.4 mm larger than the pin diameter.

5. Various Types of Membranes:

Membranes are essential in PCB manufacturing and component soldering. They can be categorized based on position and function into solder masks (Top or Bottom) and paste masks (Top or Bottom). Solder masks enhance solderability by creating light-colored spots on the green board that are slightly larger than the pads. In contrast, paste masks prevent tinning of non-pad areas on the board during wave soldering by applying a layer of paint over these sections. Thus, these two types of membranes work in tandem. This understanding clarifies settings like “solder Mask Enlargement” in the software.

6. The “flying line” has dual meanings:

It refers to the rubber band-like network connections used for monitoring during PCB design’s automatic routing. After importing components via the network table and establishing an initial layout, the Show command allows visualization of crossover connections. Adjusting component positions minimizes these crossovers, significantly improving the automatic routing rate—this step is critical. Additionally, after completing the automatic wiring, this function identifies any networks not yet routed, allowing for manual compensation. If manual compensation isn’t feasible, the second meaning of “flying line” involves connecting these networks with wires on the printed board. In large-scale automated production, these flying leads can be designed as resistance elements with a 0-ohm value and uniform pad spacing.