1. As a PCB expert, I can tell you that FR-4 is a code representing the grade of fire-resistant materials, indicating that resin materials must be able to self-extinguish after combustion. It is not a specific material name, but rather a material grade. As a result, there are various types of FR-4 grade materials commonly utilized in circuit boards. However, the majority of them are composite materials composed of Tera Function epoxy resin, filler, and glass fiber.

FR4 plates are composite materials composed of glass fiber cloth and epoxy resin. The name FR4 refers to the material specification used for glass fiber cloth. Currently, the market offers two main thicknesses of FR4 plates, namely 1.6mm and 1.2mm, and their length and width can be customized according to customer needs.

FR4 plates are one of the most commonly used materials in electronic manufacturing, mainly due to their excellent electrical, mechanical, and chemical stability. Additionally, FR4 plates also have extremely high insulation and heat resistance, which enable them to withstand high temperatures and high-pressure working environments.

Characteristics of FR4 Plates

1. Excellent performance stability

FR4 plates exhibit extremely high stability and working life, and can operate stably for extended periods in high-temperature and high-pressure environments. They can also resist electromagnetic interference and radiation interference, effectively preventing a decrease in insulation performance.

2. Super strong mechanical strength

FR4 plates can withstand mechanical stresses such as impact, vibration, and pressure, and have excellent acid, alkali, and corrosion resistance. This enables them to work stably at ordinary temperatures for long periods and to adapt to various harsh environmental applications.

3. High-precision machining performance

FR4 plates have certain processing properties and can meet the requirements of different customers. They can also undergo various machining processes such as drilling, boring, line cutting, and chip mounting, achieving high-precision and low-error process requirements.

Purpose of FR4 Plates

FR4 plates have a wide range of applications, mainly in fields such as electronics, electrical, communication, aerospace, etc. The following are their main uses:

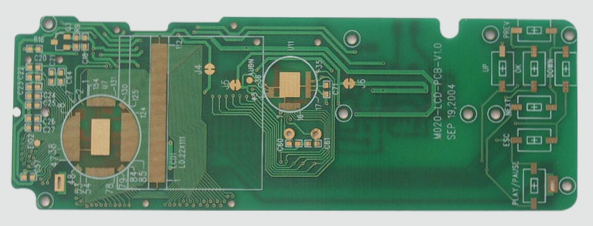

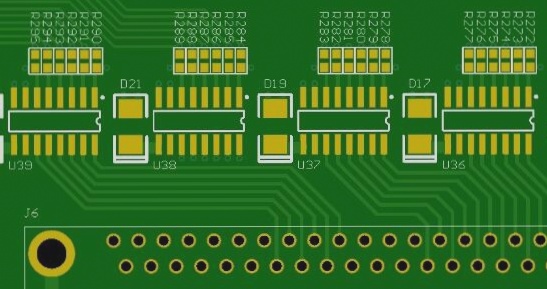

1. Circuit board

In electronic manufacturing, FR4 plates are usually used for manufacturing circuit boards. They can be used as a substrate material for circuit boards, ensuring their stability and reliability.

2. Partition and isolation materials

FR4 plates have excellent insulation performance and high-temperature stability, allowing them to be used as partition and isolation materials in power systems. This not only ensures the electrical safety of the equipment but also avoids accidents caused by electrical faults.

3. Machine elements

FR4 plates can also be used as material for machine elements, such as machine tool clapboard, automobile hood, etc. They have excellent mechanical properties and chemical stability and can be applied to different mechanical systems.

In summary, FR4 plates, as important electrical materials, have excellent electrical properties, mechanical strength, and chemical stability, and are widely used in fields such as aerospace, communication, electronics, and electrical engineering. For electronic manufacturing enterprises, choosing high-quality FR4 plates can help them improve product quality and market competitiveness.

FR4 plates are composite materials composed of glass fiber cloth and epoxy resin. The name FR4 refers to the material specification used for glass fiber cloth. Currently, the market offers two main thicknesses of FR4 plates, namely 1.6mm and 1.2mm, and their length and width can be customized according to customer needs.

FR4 plates are one of the most commonly used materials in electronic manufacturing, mainly due to their excellent electrical, mechanical, and chemical stability. Additionally, FR4 plates also have extremely high insulation and heat resistance, which enable them to withstand high temperatures and high-pressure working environments.

Characteristics of FR4 Plates

1. Excellent performance stability

FR4 plates exhibit extremely high stability and working life, and can operate stably for extended periods in high-temperature and high-pressure environments. They can also resist electromagnetic interference and radiation interference, effectively preventing a decrease in insulation performance.

2. Super strong mechanical strength

FR4 plates can withstand mechanical stresses such as impact, vibration, and pressure, and have excellent acid, alkali, and corrosion resistance. This enables them to work stably at ordinary temperatures for long periods and to adapt to various harsh environmental applications.

3. High-precision machining performance

FR4 plates have certain processing properties and can meet the requirements of different customers. They can also undergo various machining processes such as drilling, boring, line cutting, and chip mounting, achieving high-precision and low-error process requirements.

Purpose of FR4 Plates

FR4 plates have a wide range of applications, mainly in fields such as electronics, electrical, communication, aerospace, etc. The following are their main uses:

1. Circuit board

In electronic manufacturing, FR4 plates are usually used for manufacturing circuit boards. They can be used as a substrate material for circuit boards, ensuring their stability and reliability.

2. Partition and isolation materials

FR4 plates have excellent insulation performance and high-temperature stability, allowing them to be used as partition and isolation materials in power systems. This not only ensures the electrical safety of the equipment but also avoids accidents caused by electrical faults.

3. Machine elements

FR4 plates can also be used as material for machine elements, such as machine tool clapboard, automobile hood, etc. They have excellent mechanical properties and chemical stability and can be applied to different mechanical systems.

In summary, FR4 plates, as important electrical materials, have excellent electrical properties, mechanical strength, and chemical stability, and are widely used in fields such as aerospace, communication, electronics, and electrical engineering. For electronic manufacturing enterprises, choosing high-quality FR4 plates can help them improve product quality and market competitiveness.