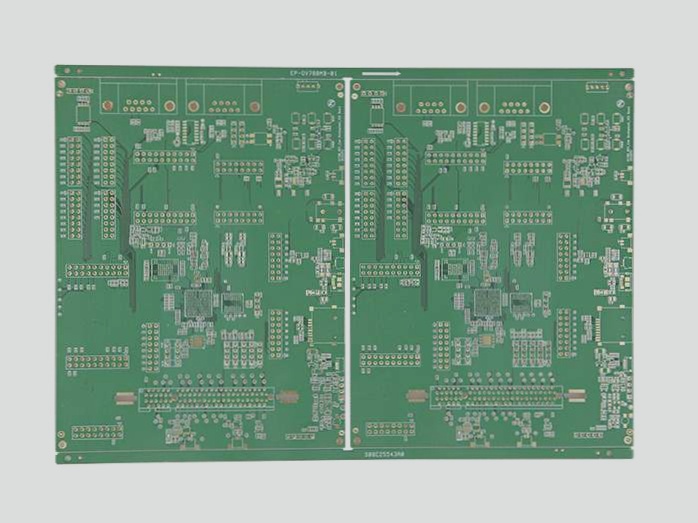

1. As a PCB expert, I would like to clarify that a hard gold PCB consists of a layer of gold with an added hardening agent to enhance durability. Hard gold is known for its durability and is an excellent choice for electroplating circuit boards. Gold is commonly used in the production of circuit boards, especially in high-wear areas like edge connectors. Gold is often utilized for the metal contacts on circuit boards.

1. Hard gold is an example of PCB surface treatment. Due to the high cost and poor weldability of hard metal, it is not an ideal weldable area. Hard gold PCBs are very suitable for applications that require friction.

2. Compared to other surface treatments, hard gold treatment provides tough frictional resistance. It is used to create gold fingers/edge fingers on circuit boards. When a PCB is designed to insert another board (such as RAM), this surface treatment is the best choice.

3. Application of Hard Gold PCB

Hard gold PCB is an ideal choice for some applications. This type of circuit board is commonly used in industrial intelligent machines. You can find them in entertainment, artificial intelligence, and educational robots. Various electronic devices use this type of PCB. For example, mobile phones, computers, and other devices all use this type of PCB. Hard gold PCBs can maintain electrical connections, making it a suitable choice for various types of applications.

4. Computer system

Gold PCBs are commonly used in computer systems for signal integrity and data transmission.

5. Telecommunication system

Hard gold PCB is an ideal material for use in telecommunications systems, including mobile phones, GPS, and satellite systems.

6. Industrial system

Gold-plated hard circuit boards are found in mechanized equipment due to its corrosion resistance and wear resistance.

7. Consumer electronics

Hard gold PCBs are used in consumer electronics such as smartphones, televisions, and smart watches.

8. The Effect of Bottom Layer on Hard Gold PCB

Gold is more useful when used together with other metals. The characteristic of the gold-plated plate is that there is a layer of nickel on the substrate, providing additional protective layer against corrosion.

9. Introduction to Hard Gold PCB Technology

Gold has good weldability, oxidation resistance, corrosion resistance, low contact resistance, and good wear resistance as an alloy. The main method for electroplating gold on circuit boards is a citrate gold bath, which is widely used due to its simple maintenance and easy operation.

10. Hard gold PCBs are widely used in intelligent AI, entertainment, educational robots, or other industrial intelligent devices. They require good wear resistance and resistance to friction, making them suitable for areas that do not require welding but are subjected to stress and friction.

1. Hard gold is an example of PCB surface treatment. Due to the high cost and poor weldability of hard metal, it is not an ideal weldable area. Hard gold PCBs are very suitable for applications that require friction.

2. Compared to other surface treatments, hard gold treatment provides tough frictional resistance. It is used to create gold fingers/edge fingers on circuit boards. When a PCB is designed to insert another board (such as RAM), this surface treatment is the best choice.

3. Application of Hard Gold PCB

Hard gold PCB is an ideal choice for some applications. This type of circuit board is commonly used in industrial intelligent machines. You can find them in entertainment, artificial intelligence, and educational robots. Various electronic devices use this type of PCB. For example, mobile phones, computers, and other devices all use this type of PCB. Hard gold PCBs can maintain electrical connections, making it a suitable choice for various types of applications.

4. Computer system

Gold PCBs are commonly used in computer systems for signal integrity and data transmission.

5. Telecommunication system

Hard gold PCB is an ideal material for use in telecommunications systems, including mobile phones, GPS, and satellite systems.

6. Industrial system

Gold-plated hard circuit boards are found in mechanized equipment due to its corrosion resistance and wear resistance.

7. Consumer electronics

Hard gold PCBs are used in consumer electronics such as smartphones, televisions, and smart watches.

8. The Effect of Bottom Layer on Hard Gold PCB

Gold is more useful when used together with other metals. The characteristic of the gold-plated plate is that there is a layer of nickel on the substrate, providing additional protective layer against corrosion.

9. Introduction to Hard Gold PCB Technology

Gold has good weldability, oxidation resistance, corrosion resistance, low contact resistance, and good wear resistance as an alloy. The main method for electroplating gold on circuit boards is a citrate gold bath, which is widely used due to its simple maintenance and easy operation.

10. Hard gold PCBs are widely used in intelligent AI, entertainment, educational robots, or other industrial intelligent devices. They require good wear resistance and resistance to friction, making them suitable for areas that do not require welding but are subjected to stress and friction.