The Challenges of Multilayer Circuit Boards

- Complexity of Multilayer Boards

- Increasing Demand in Various Industries

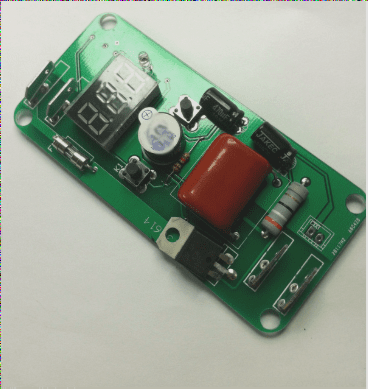

Multilayer circuit boards, typically consisting of 10 to 20 layers or more, pose challenges in processing due to their complexity. These boards are crucial in communication equipment, high-end servers, medical electronics, aviation, industrial control, and military applications. The demand for multilayer boards in sectors such as communication, base station, and aviation remains strong, driven by the rapid growth of China’s telecom market.

Current Landscape of Multilayer PCB Manufacturing

Most manufacturers capable of mass-producing multilayer circuit boards are either foreign enterprises or a few domestic companies. The production of these boards necessitates advanced technology, equipment, and experienced personnel. Moreover, stringent customer certification procedures raise the entry barrier for enterprises, resulting in longer production cycles. The number of PCB layers has become a key technical metric for assessing the capabilities of PCB enterprises.

Main Production Challenges

Compared to traditional circuit boards, multilayer boards present several difficulties, including:

- Layer Alignment Challenges

- Inner Layer Fabrication Issues

- Lamination Difficulties

- Drilling Challenges

Layer Alignment

Strict alignment tolerance control within ±75 microns is demanded by customers for each layer, posing challenges in multilayer board production.

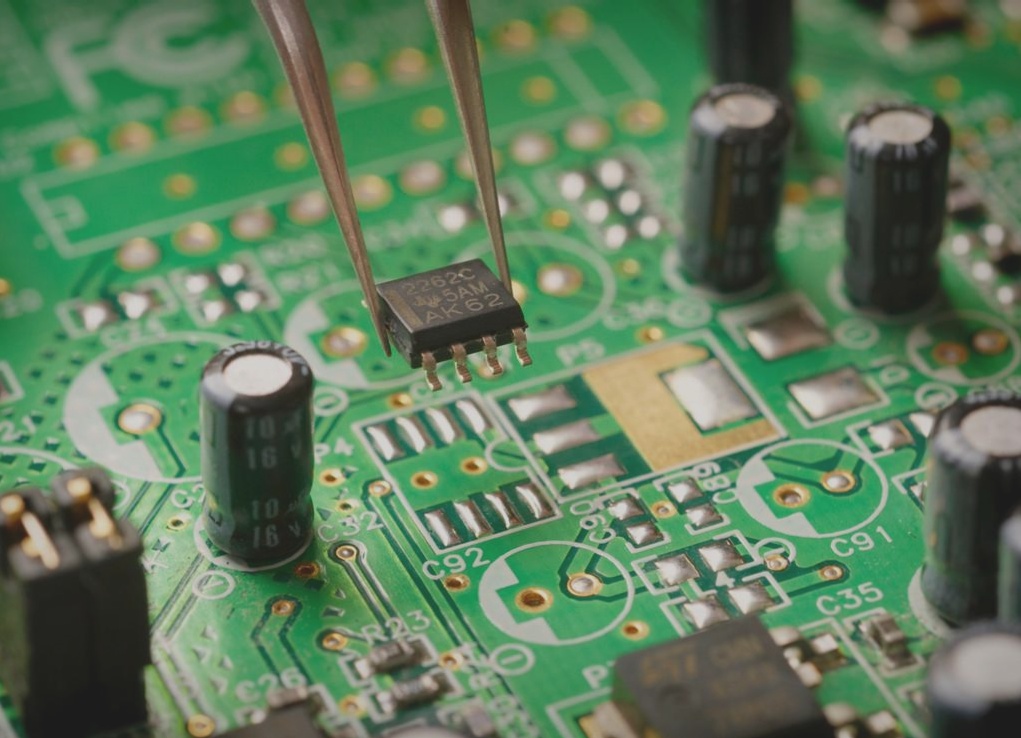

Inner Layer Fabrication

Special materials used in multilayer boards require precise production control to ensure signal integrity and avoid short circuits.

Lamination

Defects like sliding plates and resin cavities can occur during lamination, necessitating a well-designed pressing program.

Drilling

Special board materials increase drilling challenges, such as roughness and burrs, impacting the overall reliability of the boards.

Reliability Testing

Multilayer boards, being thicker and heavier, require extensive reliability testing to ensure performance and durability. These tests adhere to industry standards and specifications to validate the quality of multilayer PCBs.