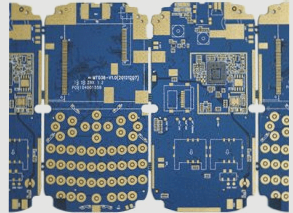

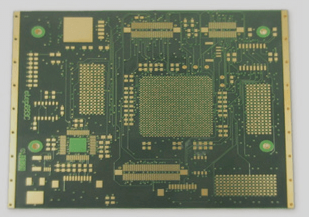

PCB Circuit Board: Enhancing Daily Life with Advanced Technology

As technology continues to progress, PCB circuit boards are becoming more integrated into our daily lives, gaining recognition for their exceptional performance and extended lifespan.

Operational Process of Circuit Board:

- Circuit Board Planning: This involves determining the PCB size, component packaging type, component placement method, and board layer structure, including choosing between single-layer, double-layer, and multi-layer boards.

- Operating Parameters Configuration: Setting environmental and layer parameters for the circuit board to streamline the design process and improve work efficiency.

- Component Layout and Adjustment: Crucial for PCB design, impacting wiring and internal layer division, often requiring manual attention for intricate circuits.

- Wiring Rule Setting: Establishing specifications for circuit wiring to enhance safety, meet production requirements, and reduce costs.

- Wiring and Adjustment: Manual or combined automatic and manual wiring methods are preferred to ensure designer expectations are met, with a focus on layout and wiring characteristics.

Performance Characteristics of PCB Circuit Board:

1. Quality Filler Material: Selecting high-quality filler materials is crucial for effective purification and machine longevity in waste gas treatment equipment.

2. Company Reliability: Assess the development history, employee count, and establishment duration of environmental protection companies to gauge product quality.

3. Easy Installation and Maintenance: Effective exhaust gas treatment equipment should be easy to install, maintain, clean, and replace.

4. Certification Verification: Thoroughly review certifications of PCB circuit board exhaust gas treatment equipment from reputable sources to ensure product quality and security.

Consumers are advised to prioritize thorough research and inquiries to make informed decisions.