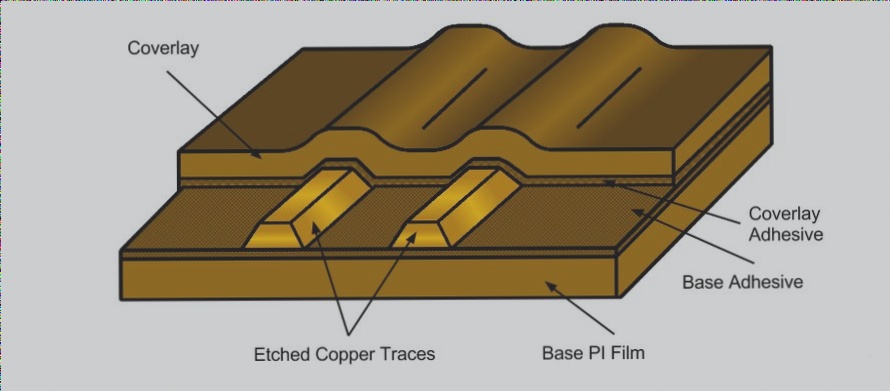

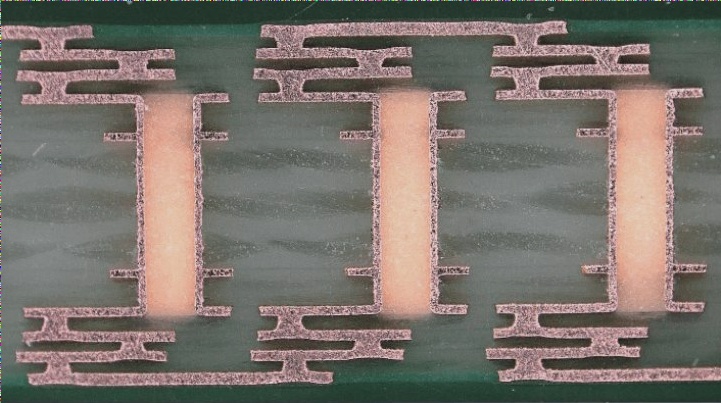

The essence of the Rigid-Flex Board is to use FPC as one or two circuit layers of the PCB, and then partially mill the Rigid part of the PCB, leaving only the flexible part.

What is Rigid-flex Board?

The birth and development of FPC and PCB gave birth to Rigid-Flex Board, a new product. Rigid-flex boards are flexible circuit boards and Rigid circuit boards with FPC and PCB characteristics formed by combining them together according to relevant technical requirements through pressing and other processes.

Advantages and disadvantages:

Advantage: Rigid-flex Board has the characteristics of both FPC and PCB, so it can be used in some products with special requirements. It has a certain flexible area and a certain Rigid area, which is of great help to save the internal space of products, reduce the volume of finished products, and improve product performance.

Disadvantages: Rigid-flex Board has many production processes, difficult production, low yield rate, and a lot of materials and labor. Therefore, its price is expensive, and its production cycle is long.

When it comes to hardware design, the cost is often not the key factor.

First, reliability: Rigid-Flex Board can solve the installation reliability problem of FPC. Connecting through connectors in FPC brings problems of installation cost, inconvenient installation, installation reliability, and easy short circuit, shedding, and other problems. The phenomenon of repairing welding between FPC and PCB after the installation of FPC is seen in the design of a cylinder machine of Hikvision for mass delivery. Rigid-Flex Board solves the problem of FPC installation reliability.

Second, comprehensive cost: Rigid-flex boards, although the price per unit area is increased, save connector costs while reducing installation time, repair rate, improved producibility, and reliability. In the mass delivery of products used, it is often effective in reducing costs.

So the calculated cost:

Rigid-Flex Board Area * Rigid-Flex Board Unit Price – Processing Time Cost – FPC Loosen and Repair Cost * Loosen Probability – Whether the management cost caused by fewer types of veneers is greater than the original PCB Area * PCB Unit Price + FPC Price + connector Price

Third, effectively improve signal quality: Better route continuity and signal integrity as connections are not made through connectors. Traditional IPC uses FPC and connectors to connect the Sensor board to the main control board. Rigid-flex board can be used to integrate the main control Board and sensor Board, which solves many problems and also meets the structural design requirements of the barrel machine.

What is Rigid-flex Board?

The birth and development of FPC and PCB gave birth to Rigid-Flex Board, a new product. Rigid-flex boards are flexible circuit boards and Rigid circuit boards with FPC and PCB characteristics formed by combining them together according to relevant technical requirements through pressing and other processes.

Advantages and disadvantages:

Advantage: Rigid-flex Board has the characteristics of both FPC and PCB, so it can be used in some products with special requirements. It has a certain flexible area and a certain Rigid area, which is of great help to save the internal space of products, reduce the volume of finished products, and improve product performance.

Disadvantages: Rigid-flex Board has many production processes, difficult production, low yield rate, and a lot of materials and labor. Therefore, its price is expensive, and its production cycle is long.

When it comes to hardware design, the cost is often not the key factor.

First, reliability: Rigid-Flex Board can solve the installation reliability problem of FPC. Connecting through connectors in FPC brings problems of installation cost, inconvenient installation, installation reliability, and easy short circuit, shedding, and other problems. The phenomenon of repairing welding between FPC and PCB after the installation of FPC is seen in the design of a cylinder machine of Hikvision for mass delivery. Rigid-Flex Board solves the problem of FPC installation reliability.

Second, comprehensive cost: Rigid-flex boards, although the price per unit area is increased, save connector costs while reducing installation time, repair rate, improved producibility, and reliability. In the mass delivery of products used, it is often effective in reducing costs.

So the calculated cost:

Rigid-Flex Board Area * Rigid-Flex Board Unit Price – Processing Time Cost – FPC Loosen and Repair Cost * Loosen Probability – Whether the management cost caused by fewer types of veneers is greater than the original PCB Area * PCB Unit Price + FPC Price + connector Price

Third, effectively improve signal quality: Better route continuity and signal integrity as connections are not made through connectors. Traditional IPC uses FPC and connectors to connect the Sensor board to the main control board. Rigid-flex board can be used to integrate the main control Board and sensor Board, which solves many problems and also meets the structural design requirements of the barrel machine.