Flexible Circuit Technology: Revolutionizing Electronic Assembly

The Evolution of Flexible Circuits

- Flexible circuits, with delicate wires embedded in pliable polymer films, enable surface mount technology and bending without functionality loss.

- Modern flexible electronics utilize Surface Mount Technology to create ultra-thin, intricate circuits that can be contorted and rolled into cylinders.

Applications of Flexible Circuits

- Flexible circuit technology is now widely used in radio communication, computing, and automotive electronics.

- They have evolved from substitutes for rigid cables to viable alternatives for rigid circuits and printed circuit boards.

Integration of Rigid and Flexible Circuits

- Rigid circuit boards are integrated with flexible circuits to cater to various application demands.

- Flexible circuit boards excel in facilitating lead lines, hosting printed circuits, enabling connectors, and integrating functionalities.

Flexible Circuit Material: The Destiny of the Film

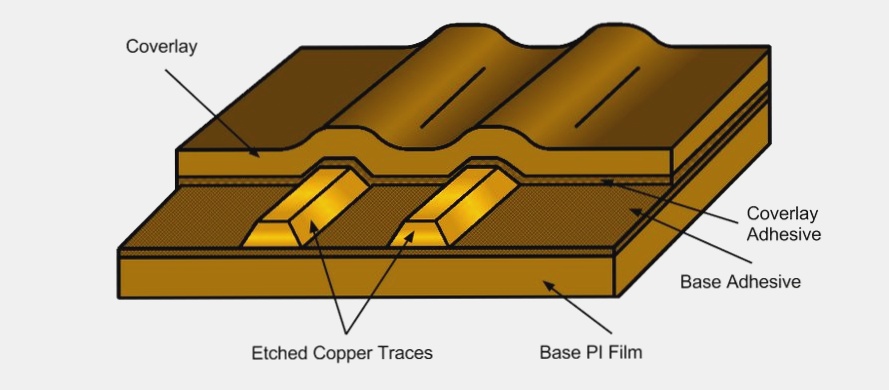

Insulation films, such as polyimide and polyester, are crucial for flexible circuit boards due to their flexibility, heat resistance, and electrical properties.

Material of Flexible Circuit: Adhesive Sheet

The adhesive sheet bonds film to metal foil, provides mechanical support, and aids in multi-layer circuit bonding.

Material of Flexible Circuit: Copper Foil

The Importance of Copper Foil in PCB Manufacturing

Copper foil plays a crucial role in the production of printed circuit boards (PCBs). It serves as the conductive layer that overlays the bonding on the insulation substrate and is selectively etched to delineate conductive lines. There are two main types of copper foil: calendered and electrolytic. Calendered copper foil is known for its superior ductility and bend resistance compared to electrolytic copper foil. It typically exhibits an elongation of 20%-45%, while electrolytic copper foil ranges from 4% to 40%. The standard thickness for copper foil is 35um (1oz), with variations including 18um (0.5oz), 70um (2oz), or even 105um (3oz). The choice of copper foil type depends on specific applications. For reactive circuit boards designed to streamline wire and connector replacement and reduce manufacturing costs, electrolytic copper foil is often the preferred option due to its enhanced current carrying capacity.

Enhancing Flexibility with Cover Layers in Flexible Circuits

The cover layer in flexible circuits plays a vital role in shielding surface conductors and strengthening the substrate. It envelops the surface of the flexible printed circuit board, providing essential insulation protection. One popular protective material for cover layers is NovaClad, developed by Sheldahl. NovaClad utilizes a proprietary technology based on vacuum metal-spraying to apply a thin layer of pure copper onto a polyimide film surface. This material is then electroplated to achieve the desired thickness, forming the base material for NovaClad. These base materials are integral in the production of Novaflex flexible circuits, eliminating the need for adhesives. Novaflex circuits are engineered to withstand harsh environmental conditions, offering superior flexibility, chemical resistance, high-temperature resilience, and efficient heat dissipation.

Reinforcing Flexible Circuits with Reinforcement Plates

Reinforcement plates are strategically placed on flexible circuits to strengthen the flexible film substrate and facilitate connections and fixations. The choice of reinforcement board materials varies depending on the application and can include polyester and polyimide sheets, epoxy glass fiber cloth boards, phenolic paper boards, or metallic plates like steel or aluminum. These reinforcement plates play a critical role in ensuring the durability and reliability of flexible PCBs.