Stencil Technology in PCB Fabrication

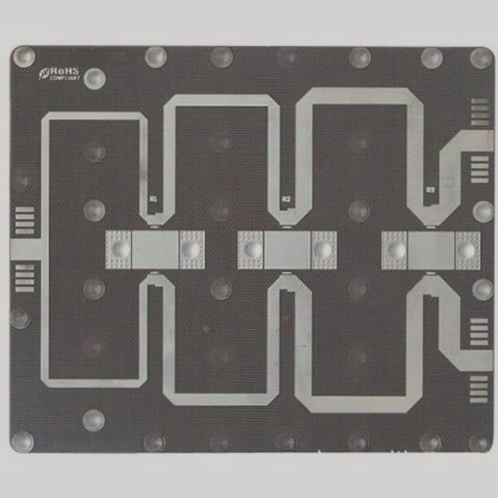

The Role of Steel Mesh in SMT Stencils

Steel mesh, also known as SMT templates, plays a crucial role in the precise application of solder paste on PCBs. Originally made from wire mesh, steel mesh has evolved over time to ensure better precision and efficiency in the SMT process.

The Evolution of SMT Stencils

From nylon mesh to copper and stainless steel meshes, the evolution of SMT stencils has been driven by the need for higher precision. Stainless steel meshes, with their resistance to rust, have become the industry standard due to their superior molding capabilities.

Classification of Steel Mesh

SMT steel mesh comes in various types, including laser templates, electropolishing templates, and electroforming templates. Laser templates, in particular, offer high accuracy in stencil openings and are widely used in the industry for their precise solder paste application.

Materials for Laser Steel Mesh Production

- PCB

- Data files in CAD formats like GERBER, HPGL, and DXF

- Design software data such as PROTEL and AUTOCAD R14

- Compressed data formats like ZIP and ARJ

- SMT solder paste layer with Fiducial Mark data

- PCB shape data and character layer data for component verification

By using advanced materials and production methods, manufacturers can create high-quality laser steel mesh stencils that meet the demands of modern SMT processes.