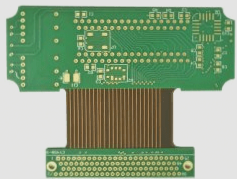

Flexible Circuit Board Plating

Pretreatment for FPC Soft Board Electroplating

- The cleanliness of the copper conductor surface is crucial for a dense coating with strong adhesion.

- Contaminants like adhesive or ink can affect the plating process and weaken bonding strength.

- Strong alkaline abrasives are used to remove stubborn contaminants.

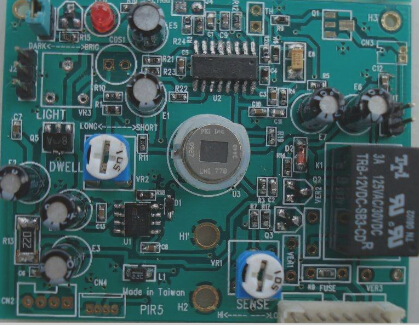

Thickness Considerations for FPC Electroplating

- Electric field intensity affects the plating thickness, with narrower wires resulting in thicker plating.

- Shunt cathode patterns can help balance current distribution for uniform coating thickness.

- Different standards apply to various plating requirements, such as fusion welding and anti-corrosion applications.

Stains and Dirt in FPC Electroplating

- Inadequate rinsing can lead to stains, dirt, and discoloration on the plated surface.

- Flexible printed boards are prone to color changes due to residual plating solutions.

- Thorough rinsing and drying treatments are essential to prevent these issues.

Flexible Circuit Board Electroless Plating

- Electroless plating is used when the line conductor cannot serve as an electrode.

- Plating solutions with high chemical activity can seep beneath the covering layer.

- Quality control during lamination is crucial to avoid penetration of the plating solution.

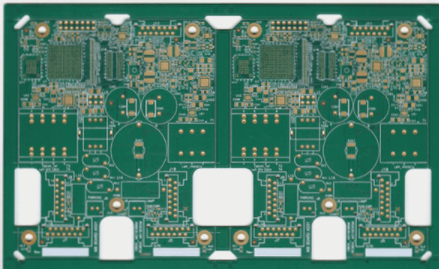

Hot Air Leveling of Flexible Circuit Boards

Hot Air Leveling Process in PCB Fabrication

Hot air leveling, initially used for coating rigid printed circuit boards with lead and tin, has now found application in flexible printed boards (FPC) due to its simplicity. This technique involves immersing the board vertically in a molten lead-tin bath and then removing excess solder with hot air.

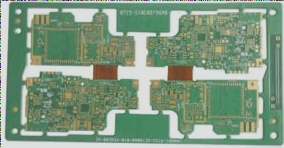

Challenges for Flexible Printed Boards

- Harsh Conditions: The hot air leveling process can be harsh for FPCs.

- Secure Immersion: FPCs need to be secured between titanium steel screens before immersion in molten solder.

- Cover Layer Issues: Weak bonding between the cover layer and copper foil can lead to solder penetration.

- Moisture Absorption: Polyimide films in FPCs easily absorb moisture, which can cause bubbling or delamination during the hot air leveling process.

To address these challenges, it is recommended to implement drying and moisture-proof management measures before subjecting FPCs to the hot air leveling process.

Latest Updates:

Recent advancements in hot air leveling technology have focused on improving the bonding strength between the cover layer and copper foil in flexible printed boards. This development aims to enhance the overall reliability and performance of FPCs during the PCB fabrication process.

Looking Ahead:

Future research in hot air leveling is expected to explore innovative solutions for minimizing moisture absorption in polyimide films and optimizing the soldering process for FPCs, further advancing the capabilities of flexible printed circuit boards in various electronic applications.