Data Requirements for First Article Inspection of PCBA Processing

1. Importance of Accurate Information

- Production, engineering, and quality departments must verify the accuracy of information.

- Ensure correct samples are available for reference, preferably provided by the customer.

- Product drawings, process documents, BOM, and technical documents are essential.

2. Key Points of PCBA First Inspection

- The first piece in the order includes panels for SMT modeling and testing.

- Inspect the first panel to ensure quality at the start of a shift or production.

- For ECN and process changes, perform necessary quality measurements.

3. Attention Points in PCBA First Inspection

- Implement protective measures like electrostatic protection.

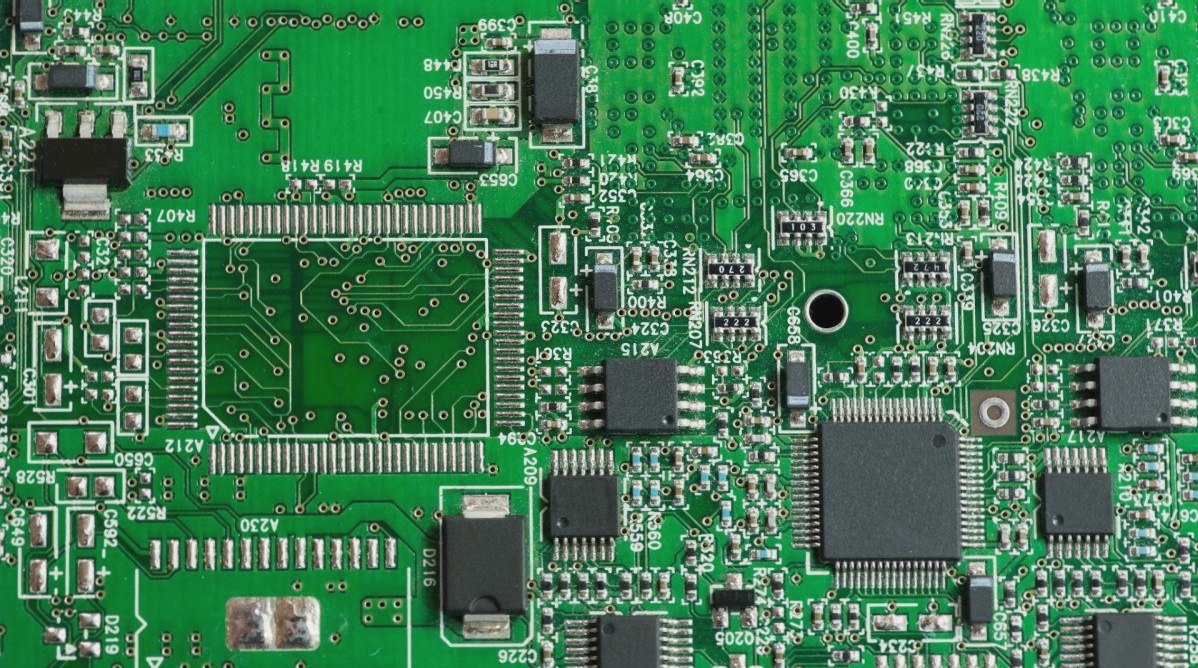

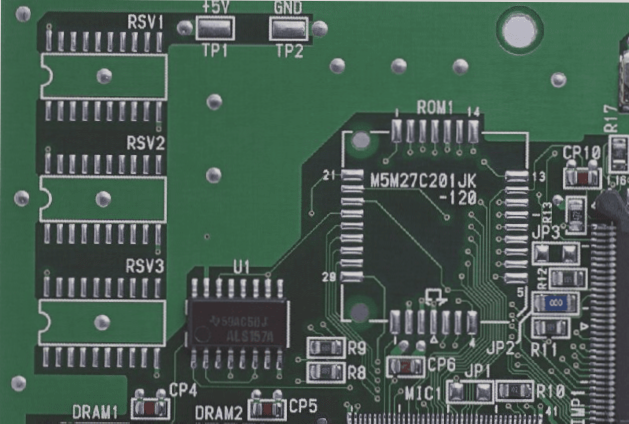

- Verify component positions, polarity, and quality.

- Check soldering quality and mark passed pieces according to regulations.

4. Inspection Mechanism of PCBA Processing

- Self-inspection by engineers, mutual inspection by operators, and full inspection by quality inspectors.

- Use multimeters, ECR bridges, and X-ray inspection for quality verification.

- The three-inspection system is based on the first piece, ensuring document accuracy and sample correctness.

Summary

Effective first article inspection in PCBA processing is vital for early issue detection and prevention of scrap batches. It helps identify systemic problems and ensures product quality, ultimately reducing the risk of producing defective products.