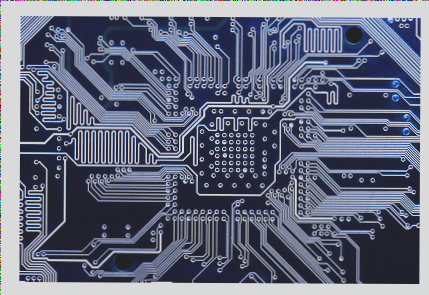

PCB Board and Different Types of Vias

The PCB board is composed of multiple layers of copper foil circuits, with connections between these layers established through vias.

Through Hole (PTH)

This is the most common type of via on a PCB. It is created by drilling or laser cutting directly through the board, allowing light to pass through. Through holes are cost-effective but may occupy more space on the PCB, similar to adding a staircase in a building that connects only specific floors.

Blind Hole (BVH)

A blind via connects the outermost circuit layer to an inner layer through a plated hole. This type of via requires precise drilling depth control and is used to maximize space utilization on the PCB. It can be likened to a staircase in a building that connects only certain floors, such as the first to the second floor.

Buried Via (BVH)

A buried via connects two inner circuit layers without reaching the outer layers. It must be drilled before the layers are bonded together, making it a more time-consuming and expensive option. Buried vias are commonly used in HDI PCBs to optimize space on other layers, similar to a staircase that only connects specific floors without access to the outer levels.