What is the concept of PCB circuit?

PCB stands for Printed Circuit Board. This is a printed circuit board that has a structure of many different layers and has no conductive function. In all these electronic components are connected together on the same circuit board and have a base to support the bottom.

If the device does not have a PCB, the components are connected to each other by a type of conductor with the function of increasing complexity and low reliability. Thanks to that, they can’t make a big board compared to the motherboard.

Printed circuit boards have a structure consisting of many different layers

Classification of PCB boards

Currently, a number of PCB boards are used in applications, so you should consider researching to choose the most suitable type of PCB.

Sort by the number of layers in the circuit board

Single layer PCB

Single-layer PCB is also known as single-sided PCB. This type of PCB has a simple structure and is most commonly used because it is easy to design and manufacture. One side of the circuit board is coated with any other conductive material. And it is used as a conductive material for PCBs, because copper’s conductive properties are very good.

Double layer PCB

Another name for double-layer PCB is double-sided PCB. In this type of PCB there is a small size, making the circuit compact, very flexible and low cost, thanks to a thin layer of conductive material. For example, there is copper on both the top and bottom of the board.

Multilayer PCB

Multilayer PCB means more than two layers. It means that this type of board has at least three conductive layers made of copper. The board glue is sandwiched between the insulation layers to ensure that the heat generated won’t damage any components of the circuit.

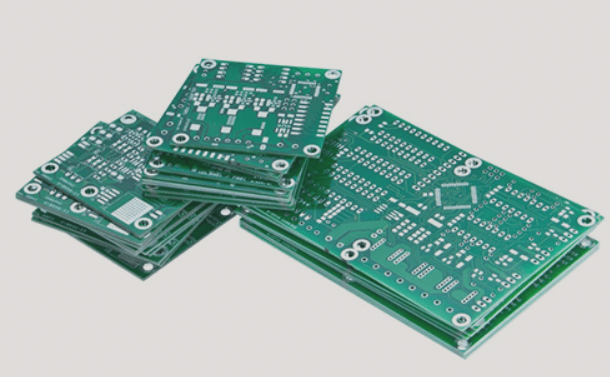

PCB board classification

Circuit board components support device protection

Classification by hardness of PCB

Flexible PCB

Flexible PCB is also known as Flex circuit. This type of PCB is often used from flexible materials such as PEEK (polyether ether ketone) or polymide or transparent conductive polyester film. This type of circuit board is usually folded or twisted together.

Aluminum base PCB

Aluminum base PCB is a flexible – rigid PCB (flex-rigid PCB). This is a combination of rigid PCB and flexible PCB, consisting of layers of flexible PCB bonded to multiple layers of rigid PCB. In mobile phones, cars and digital cameras…, they are commonly used.

Rigid PCB

Similar to flexible PCB, rigid PCB board has different number of layers and is classified as single layer, double layer or multi-layer. On the other hand, unlike flexible PCBs, this type of PCB cannot be folded or bent. Therefore, it is called a rigid PCB.

Moreover, the durability of this type of PCB is relatively high. Therefore, they are applied in many parts of the computer’s structure such as CPU, RAM, and GPU. Currently, the single-sided rigid circuit board is the most designed and put into production. People can reduce the size of rigid PCB by integrating 9-10 layers on the same circuit board.

Flexible – Rigid PCB

This PCB board consists of rigid PCB layers, which are bonded with flexible PCB layers. Therefore, they are considered as a combination of flexible PCB and rigid PCB. The device is used in applications for mobile phones, digital cameras and automotive electronics.

Classification by mounting system

Through-hole PCB Board

There are many holes on the surface of this type of PCB, making it easy to solder components to the pad on the opposite side of the PCB. Mechanically, through-hole PCB technology helps to preserve components and is more secure than making holes for PCBs by drilling to increase production costs. This technology is most suitable for single-layer PCB, which makes installation easy and the difficulty of layers is increasing day by day.

Surface Mounted PCB

For this type of PCB, components are fabricated, making the installation on the board convenient. These accessories are called SMD adhesives and are mounted directly onto the circuit without going through holes.

How materials are used to make PCB boards?

As can be seen, the main material of the PCB board is a flexible or rigid dielectric plate. This plate is used in conjunction with conductive materials such as copper arranged above. Besides, the dielectric plate is coated with glass or composite epoxy coating. Specifically, the materials used to make PCB boards are:

PCB board equipment

FR4

FR stands for Fire Retardent. Among the types of PCBs manufactured, this material coated with glass is the most commonly used. Based on epoxy-glass compounds, FR4 is the most synthesized and applied, because it provides the best mechanical strength.

FR-1 and FR-2

FR-1 and FR-2 are made from paper materials and phenolic compounds. They are used for single layer PCBs. The characteristics of FR1 and FR2 are similar. The only difference is the internal glass transition temperature. The glass transition temperature level is higher than that of FR2. These materials are divided into standard and non-hydrophobic and halogen-free grades.

CEM-1

This is a material made from paper and two layers of glass epoxy textile, along with a phenolic compound. At the same time, this fuel is used for single-sided PCB and CEM-1 is used to replace FR4, but the cost of CEM1 is higher than FR4.

CEM-3

The CEM-3 material is a compound between glass epoxy which is white in color and is used in double-layer circuit boards. Furthermore, the durability of CEM-3 is lower than that of FR4, but it is cheaper than FR4. Therefore, this material is a good alternative to FR4.

PCB board manufacturing

Polyimide

Polyimides are used in flexible PCBs. It is made from materials such as rogers, kepton, dupont. Polyimide materials have good electrical conductivity, can be used over a wide temperature range and high chemical resistance. The operating temperature of this material is from -200◦C – 300◦C.

Prepreg

Prepreg is impregnated before. This is a fiberglass impregnated with resin. This resin is dried and when heated, it melts and binds. Prepreg can be bonded similar to FR4 material. Currently, Prepreg has many resins and resins that meet SR standards, MR medium resins or high HR resins.

Depending on the material, they have different thickness requirements. Similar structure of layers and impedance. This material has a high glass transition temperature and is generally halogen-free.

For more information about PCB products, please contact WellCircuits immediately.