Advantages of UV Laser Technology in PCB Manufacturing

UV laser technology has revolutionized the PCB industry, offering precise and efficient solutions for cutting and drilling circuit boards. Let’s explore the benefits of UV laser systems:

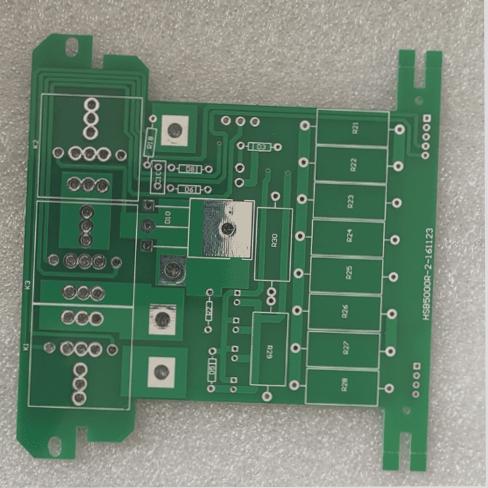

1. Precision and Clean Cuts

UV lasers produce minimal thermal effects, resulting in clean and precise cutting edges. Compared to CO2 lasers, UV lasers offer superior cutting quality.

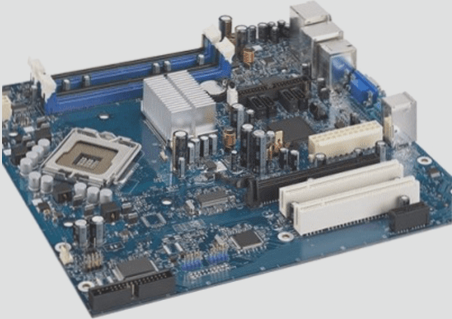

2. Versatility in Applications

UV lasers are ideal for cutting and marking rigid boards, flex boards, rigid-flex boards, and their accessories. They are versatile and can handle various PCB materials with ease.

3. Minimal Thermal Impact

UV laser pulses affect the material for microseconds without significant thermal effects. This ensures that nearby components, lines, and solder joints remain intact without burrs.

4. Easy Integration with CAD Software

LPKF UV laser systems come equipped with CAM software for seamless integration with CAD data. This allows for precise editing of cutting paths and selection of processing parameters for different materials.

5. Suitable for Mass and Sample Production

Whether you require mass production or sample prototyping, UV laser systems offer the flexibility to meet your PCB manufacturing needs efficiently.

Conclusion:

With its precision, versatility, and minimal thermal impact, UV laser technology is transforming the way PCBs are manufactured, providing cost-effective and high-quality solutions for the industry.