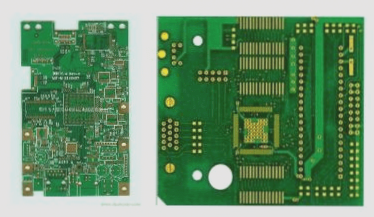

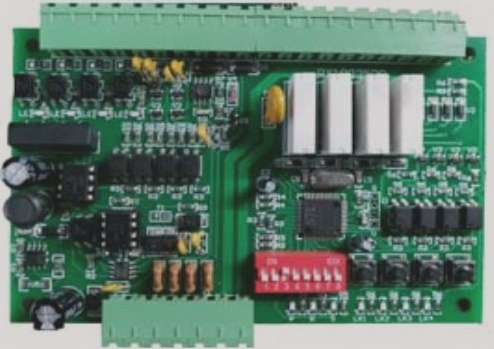

As the renewal of electronic products accelerates, the amount of printed circuit board (PCB) waste is also increasing. The pollution caused by waste PCBs has garnered the attention of countries around the globe. Waste PCBs contain heavy metals such as lead, mercury, and hexavalent chromium, as well as flame retardants like brominated biphenyl (PBB) and brominated diphenyl ether (PBDE). These substances can severely contaminate groundwater and soil, posing significant risks to human health and well-being. Old PCBs contain nearly 20 types of non-ferrous and rare metals, which have high recycling and economic value.

A physical method.

The physical method is a recycling approach that employs mechanical means, leveraging the distinct physical properties of PCBs.

It broke 1.1.

The purpose of crushing is to maximize the separation of metal and organic matter in waste circuit boards, thereby enhancing selection efficiency. Studies indicate that when crushed to 0.6 mm, metal can achieve nearly 100% dissociation, although the choice of crushing method and grade depends on the subsequent processing requirements.

Separation involves using the density, particle size, conductivity, magnetic permeability, and surface characteristics of the materials to achieve segregation. Currently, technologies such as wind shaker separation, flotation separation, cyclone separation, and float-sink separation are employed.

—

Let me know if you need further adjustments!

**2 Kinds of Supercritical Technology Processing Methods**

Supercritical fluid technology involves extraction and separation by leveraging the effects of pressure and temperature on the solubility of supercritical fluids, without altering their chemical composition. Compared to traditional extraction methods, supercritical CO2 extraction offers advantages in terms of environmental impact, convenience, low toxicity, and lack of residue.

There are two primary research directions for supercritical fluid treatment of waste PCBs. First, supercritical CO2 fluid is used to extract resin and brominated flame retardants from printed circuit boards. When the resin adhesive is removed using supercritical CO2, the copper foil and glass fiber layers in the PCB can be easily separated, enabling efficient material recycling. Second, supercritical fluid can be employed to extract metals directly from waste PCBs. Reports by Wai and others indicate that lithium carbamate (fluorinated diethyl disulfide) serves as a complexing agent. They successfully extracted CD2Cu2Zn2Pb2Pd2As3Au3Ga3 and Sb3 from simulated cellulose filter paper or sand, achieving extraction efficiencies above 90%.

Despite its advantages, supercritical processing technology has several shortcomings, including high extraction selectivity, the need for entrainers that may harm the environment, and extraction pressures exceeding equipment capabilities. Additionally, the high temperatures required during the extraction process lead to increased energy consumption.

**3 Chemical Methods**

Chemical treatment technology utilizes the chemical stability of various components in PCBs for extraction.

**3.1 Heat Treatment Method**

The heat treatment method primarily employs high temperatures to separate organics from metals. This includes incineration, vacuum cracking, and microwave methods.

**3.1.1 Incineration Method**

In the incineration method, electronic waste is crushed to a specific particle size and placed in an incinerator, where organic components decompose, separating gas from solid residues. The incineration byproducts include bare metals or oxides and glass fibers, which can be recycled through physical and chemical methods. Organic gases are subsequently combusted in a secondary incinerator. However, this method generates substantial exhaust gases and toxic substances.

**3.1.2 Cracking Method**

Industrial cracking, or dry distillation, involves placing electronic waste in a sealed container, where it is heated to decompose organic matter into oil and gas under controlled temperature and pressure conditions. After condensing the vapors, the products can be recycled. Unlike incineration, vacuum pyrolysis occurs anaerobically, significantly reducing harmful gas emissions.

**3.1.3 Microwave Processing Technology**

Microwave recycling begins with breaking down electronic waste, followed by heating the organic components using microwaves. Heating to around 1400°C allows glass fibers and metals to melt into a glass material. After cooling, metals such as gold and silver can be extracted as solid balls, while the remaining glass materials are suitable for recycling as building materials. This method distinguishes itself from traditional heating approaches by offering high efficiency, an elevated resource recovery rate, and lower energy consumption.

**3.2 Hydrometallurgy**

Hydrometallurgy primarily relies on the dissolution of metals in acidic solutions—such as nitric acid, sulfuric acid, or aqua regia—to extract metals from electronic waste for recovery from the liquid phase. This technique is widely adopted for electronic waste treatment and offers advantages over pyrometallurgy, including lower emissions, simpler metal residue disposal, and significant economic benefits.

**4 Kinds of Biotechnology**

Biotechnology employs microbial adsorption and microbial oxidation to facilitate metal recovery. Microbial adsorption can be categorized into two types: direct fixation of metal ions by microbes and fixation of metal ions with hydrogen sulfide produced by bacteria. The latter process forms flocs that settle when ion saturation occurs. Additionally, microbial oxidation can convert precious metals like gold into soluble forms, facilitating their recovery. While biotechnological extraction methods are characterized by straightforward processes, low costs, and ease of operation, they typically exhibit lower long-term infiltration rates.

**Conclusion**

E-waste is a valuable resource, underscoring the importance of advancing metal recycling technologies. From both economic and environmental perspectives, e-waste represents a crucial area of research and application. Given the complex and diverse characteristics of e-waste, the future of e-waste technology lies in the industrialization of processing methods. Maximizing resource recovery through scientific advancements not only helps protect the environment but also facilitates resource recycling and energy conservation, thereby promoting sustainable economic and social development.