1. To enhance the printing speed and boost production capacity during the screen printing of green paint on PCB surfaces, operators often add a thinning solvent to dilute it, alongside the hardener. Common solvents include “anti-white water” (BCS; Buty Cellosolve) and others. Typically, suppliers of green paint for PCBs recommend adding only 15ml or 1-3% (by weight) to one kilogram of ink. Lowering the viscosity not only facilitates easier printing but also minimizes the drying of ink piles on the mesh cloth at the processing site where air conditioning works in conjunction with air blowers.

2. After adding the hardener and diluent to the ink when the can is opened, it’s crucial to achieve a uniform overall viscosity (around 150 PS is ideal). This can be done using a propeller-type or L-shaped paddle agitator, or by gently stirring with a shaker for more than half an hour. Occasionally, in the interest of speeding up the process, it may be tempting to shorten the stirring time, increase the scraper speed, add excessive solvents, or stir vigorously without allowing for defoaming. This often results in air bubbles appearing at the edges of the printed lines once the screen printing hardens, which are highly noticeable and frequently lead to rejection by QA or customers.

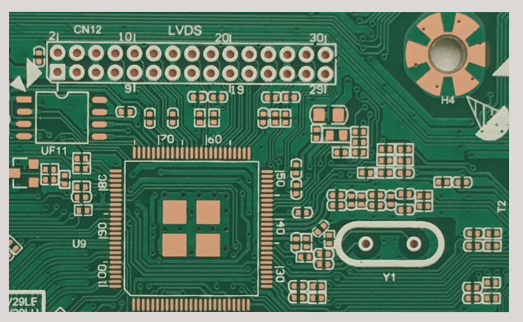

3. Air bubbles can also form during field screen printing on PCBs. If the printing is executed too quickly, bubbles may arise. The “leeward side” of densely packed parallel lines, aligned with the direction of the squeegee, is particularly prone to trapping air. In severe cases, air bubbles may also occur on the “windward side.” Typically, the thickness of the shoulder on the leeward side is quite minimal, and there can even be insufficient ink on the substrate with similar spacing.

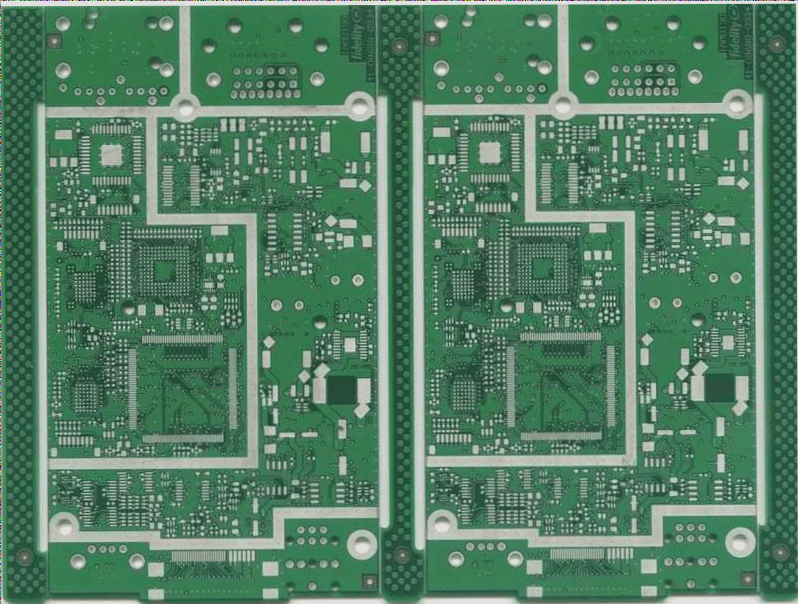

1. There are fewer bubbles in the dense line areas. The diagonal web and the technique of applying the ink-blocking dot screen should help mitigate some air bubble issues. Bubbles typically form at the edges of the dense line areas and are seldom found on the open board surface. Magnified images of the photopic and scotopic sections support this observation.

2. All images are taken at 100X magnification. Although the green paint on the PCB surface is not visibly green, it can still be easily distinguished from other materials.

3. Enlarged images at 100X and 200X under dark vision show the S/M layer is distinctly green.

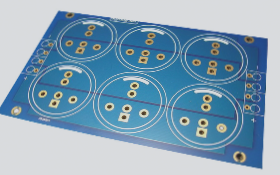

4. In the process of screen printing the liquid photosensitive PCB surface green paint (LPSM), bubbles frequently appear between fine lines. In the past, when the LPSM formula was not fully developed, a “dry film” photosensitive solder mask was also widely used. To avoid cutting from drops on thick circuits, the thickness of this dry film was approximately 4 mils. The application method involved using a vacuum process to heat and press the film onto the board’s surface, which naturally prevented bubble formation. The image below, taken by the author 13 years ago, depicts a DuPont product, Vacrel 8040, designed for sodium carbonate resolution. This solder mask film exhibits excellent adhesion and surface flatness; however, it has been phased out of mass production due to adhesion issues, complex application, and high costs.

5. Nevertheless, the recent emergence of thin P-BGA substrates necessitates that the thickness of the green paint on the PCB surface exceeds 1 mil, and that plug holes remain flat and bubble-free to avert the “popcorn” disasters lurking in hard-to-reach areas. This “green paint on dry film PCB surfaces” using vacuum construction seems poised for a revival.

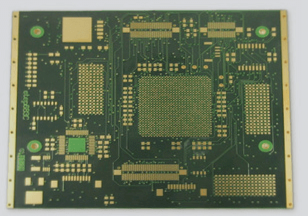

6. The green paint on the surface of the 200X circuit PCB is applied using an electrostatic automatic spraying method, which not only reduces air bubbles but also ensures the shoulder thickness exceeds 0.8 mil, far surpassing specifications. However, this method consumes a considerable amount of paint.

7. The significance of the green paint thickness on PCB surfaces is crucial. The primary roles of this paint are solder protection and wire safeguarding. Since the green paint accompanies the PCB during shipping, its quality directly influences downstream operations and significantly impacts the final product. Particularly with new BGA and CSP types, it is essential to eliminate air bubbles and ensure adequate paint thickness. This ensures the circuit board can withstand various harsh environments, protecting wires from external contaminants and preventing reliability crises.

8. The IPC-SM-840B specification clearly defines the thickness requirements for green paint on PCB surfaces. For Class 3 high-reliability boards, the minimum thickness is set at 0.7 mil. In contrast, Class 2 commercial boards (such as computers and peripherals) have a lower limit of 0.4 mil. However, during the revision from the B to the C edition of the specification in June 1996, this thickness requirement was eliminated. I believe this change reflects the increasing speeds of signal transmission. According to Maxwell’s equations, the propagation speed of electromagnetic waves is directly proportional to the speed of light (C) and inversely proportional to the square root of the dielectric constant of the medium (Dielectric constant; also known as Relative Permittivity).

9. The relative permittivity of air and vacuum (εr) is the lowest, set at 1, meaning that the speed of electromagnetic waves in air equals the speed of light. Generally, the εr of the green paint on PCB surfaces is around 3.0 (measured at a frequency of 1 MHz). Thus, when the thickness of the green paint decreases (approaching that of air), the transmission speed of square wave signals (a type of electromagnetic wave) also increases. Consequently, the emphasis on the thickness of green paint on high-speed computer PCBs has diminished.

10. However, when the green paint thickness is inadequate—especially for power lines with higher currents and broader widths—the shoulder thickness still needs to be at least 0.4 mil to prevent issues in challenging environments and during operation that could accelerate corrosion. After six months of product assembly, power cords that passed through inadequately thick green paint were compromised by foreign objects in harsh conditions. The thickness of the green paint on the PCB surface can be observed in the slice.

11. Insufficient green paint thickness can lead to copper wire corrosion, as shown in the 10X image, while the PCB surface with thicker lines is coated with green paint. The application of green paint on the PCB surface involves scraping ink from left to right; it is essential to monitor the thickness before and after scraping.

12. In early PCB tin melting processes, post-assembly, the molten tin layer on the original wire can flow again, causing the green paint on the PCB surface to warp. On the right, the green paint is printed over the bare copper wire (SMOBC) of the PCB and remains unaffected by high heat.