Possible Causes of Ruptured PCBA MLCC Multilayer Ceramic Capacitors

In the realm of capacitors, the development of micro cracks can often lead to open circuit conditions and an increase in insulation resistance (IR). Interestingly, when a microcrack occurs, it may result in decreased insulation resistance, leading to current leakage short circuits. This issue can be attributed to layer-to-layer short circuits caused by ruptures in the multilayer structure.

Exploring Micro-Crack Causes in Multilayer Ceramic Capacitors

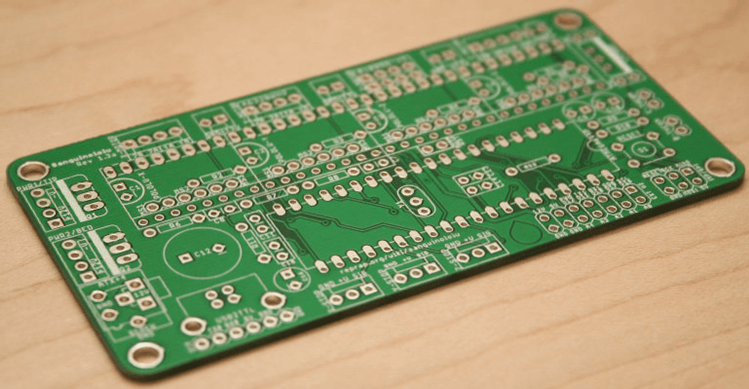

If you are unfamiliar with the structure of MLCC, it is recommended to refer to previously published articles detailing the composition and processes of multilayer ceramic capacitors (MLCC).

Main Categories of MLCC Rupture Causes:

- Thermal Shock Failure

- Extrinsic Defect and Overstress Failure

- Intrinsic Defect

Principle of Thermal Shock Failure:

Rapid temperature fluctuations around PCB components can induce thermal shock, commonly encountered during processes like wave soldering, reflow, touch-up, or repairs.

**High Temperatures:** During the production of multilayer ceramic capacitors (MLCCs), various materials with different coefficients of thermal expansion and thermal conductivity are used. When these materials experience rapid internal temperature changes, differing volume change rates can lead to PCB cracking.

Cracks typically initiate from the weakest structural point or where stress is most concentrated. Common locations include the exposed end next to the central ceramic interface or areas with maximum mechanical tension (often at the four corners where the material is hardest).

**MLCC Thermal Shock Cracking Phenomena:**

- Nail-shaped or U-shaped cracks

- Microcracks hidden within the capacitor

- Cracks originating from the exposed central part or the lower half of the junction between the central ceramic end and the exposed end

**The Failure Principle of PCB Overstress:**

Distortion and fractures are typically caused by external forces (extrinsic factors) during SMT assembly or product fabrication. Possible causes include:

- Improper gripping of components by the pick & place machine

- Excessive lifting or placing of parts during capacitor mounting

- Non-uniform land-pattern layouts or asymmetric solder paste application

Common Causes of Cracking in PCB Capacitors

- Thermal shock during soldering process and substrate bending can lead to cracking.

- Issues during capacitor wave soldering, like inadequate preheating temperature or excessive soldering temperatures, may result in cracks.

- Direct contact between soldering iron and capacitor body during PCB touch-up can cause local overheating and cracking.

- Bending the substrate during board cutting or machine assembly can induce cracks post-welding.

Understanding Different Types of Failures

When the board bends under mechanical stress, cracks can form outside the ceramic’s termination interface at a 45-degree angle.

Distortion and Fracture Failure

In cases of minor SMT stage ruptures, they may not be detectable via metallography. However, ruptures and distortions post-SMT production are usually identifiable through metallographic examination.

MLCC Material Failure and Rupture

MLCC material failures can be classified into three main defect categories originating from internal capacitor issues, compromising product reliability due to improper processing or material selection.

- Electrode interface failure and bond line rupture (Delamination): Larger cracks may occur due to high void levels in the ceramic or voids between the dielectric layer and opposing electrode, leading to dielectric layer cracking and potential leakage risks.

- Voiding: Voids between adjacent inner electrodes can cause short circuits and leakage currents, affecting capacitance. Poor process control, like contamination or inadequate sintering of ceramic capacitor powder, is often the root cause.

- Firing cracks: Cracks forming perpendicular to electrodes, often from edges or terminals, can lead to excessive current leakage. Excessive cooling during the manufacturing process is a primary cause.

Summary of Capacitor Cracking

Cracks induced by thermal shock propagate from the capacitor’s surface inward, while ruptures from mechanical tension can appear on the surface or within the component at 45-degree angles. Material failures can lead to cracks perpendicular or parallel to internal electrodes. Thermal shock-induced ruptures extend from one terminal to another, and fractures caused by the pick and place machine may have multiple fracture points beneath the terminal. Distortions in the circuit board usually result in a single rupture point.