IPC Assembly Standards at WellCircuits

- The importance of PCB in technological advancements cannot be overstated, enabling downsizing and cost-effective solutions.

- IPC standards play a crucial role in ensuring adherence to industry standards throughout the manufacturing process.

- IPC consists of over 4,800 member companies, including designers, suppliers, and manufacturers from the global electronics industry.

Why Do IPC Standards Matter?

- IPC standards determine whether manufactured PCBs meet required safety, reliability, and performance standards.

- Adhering to IPC standards ensures high-quality and reliable circuits, satisfying end customers.

For more information on the cost of PCB assembly, visit Cost of PCB Assembly.

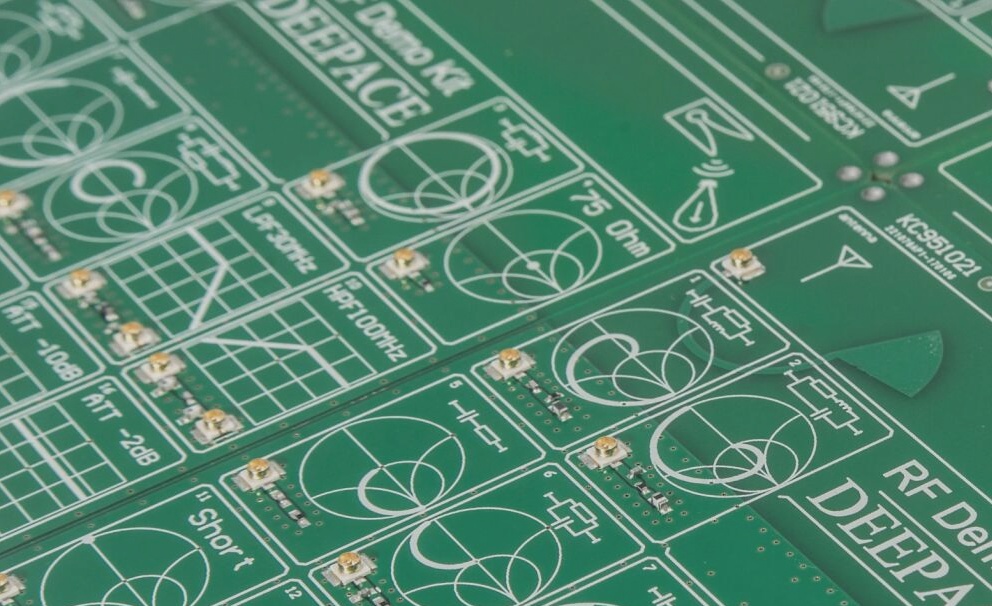

IPC Standards Used In The Manufacturing of Your PCB

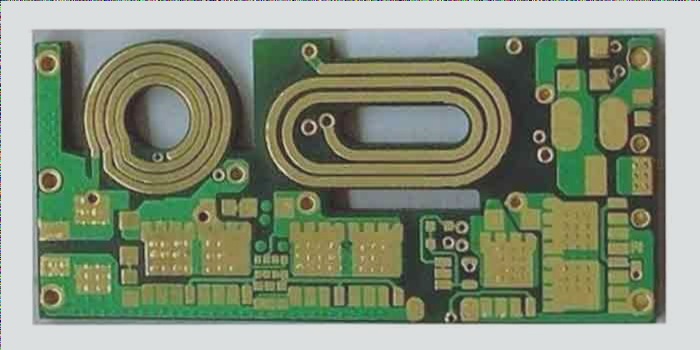

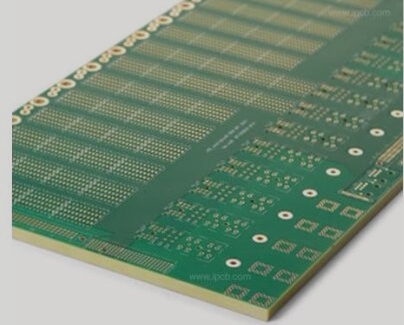

- Printed Circuit Boards undergo various manufacturing processes, ensuring reliability in end products.

- IPC-A-610 standard focuses on the acceptability of electronic assembly, covering handling and installation methods.

- IPC J-STD-001G standard is used for soldered electrical and electronic assemblies, detailing manufacturing requirements.

When manufacturing printed circuit boards, it is essential to consider various IPC standards to meet industry requirements.

IPC Standards for PCB Manufacturing

-

IPC-A-600:

The IPC-A-600 focuses on the quality assessment of Printed Circuit Boards (PCBs) during the manufacturing process.

-

IPC-A-630:

This standard is essential for inspecting box builds and ensuring the quality of electronics manufacturing processes.

-

IPC/WHMA-A-620C:

IPC/WHMA-A-620C is crucial for inspecting cable wire requirements and acceptance criteria in PCB assemblies.

-

IPC-7711/7721C:

For reworking, modifying, or repairing manufactured PCBs, the IPC-7711/7721C document is utilized.

Enhancing PCB Manufacturing Practices

Accessing IPC standards is vital for ensuring products meet industry benchmarks. However, staying updated with the latest modifications is equally crucial for optimal manufacturing processes.

Contract manufacturers can benefit from having certified IPC trainers within their teams to keep employees informed and up-to-date with the evolving standards.

Certified IPC trainers not only benefit the employer but can also provide training to end customers or suppliers, fostering better communication and understanding throughout the manufacturing chain.

Optimizing Your PCB Manufacturing Business with IPC Standards

Adhering to IPC standards is fundamental, but true success in PCB manufacturing involves a comprehensive understanding and implementation of these guidelines.

By focusing on details and following Design for Manufacturability (DFM) rules, businesses can detect even the smallest defects and ensure optimal manufacturing processes.

Important Considerations for PCB Manufacturing

- Adhering to IPC standards is crucial for your PCB manufacturing process.

- Follow key guidelines for a successful PCBA design to meet industry standards.

- Avoid skipping important processes like handling electrostatic discharge.

The Future of PCB Manufacturing

The global market for PCB manufacturing is set to expand in the coming years. With innovations continuously growing, the industry shows promising growth opportunities for the future.

Why Choose WellCircuits Electronics Services?

- WellCircuits Electronics Services offers top-quality PCBs to meet your electronic industry needs.

- Professionals at WellCircuits ensure all products meet industry specifications.

How to Get Started

If you’re looking for the best PCB services, contact WellCircuits Electronics Services via email at info@wellcircuits.com or phone at 224-366-0290. Benefit from attractive deals and efficient service tailored to your requirements.