Flexible Circuit Boards (FPC) Revolutionizing Electronics Manufacturing

- By 2030, electronic components are projected to make up 50% of costs in smart electronics, up from 30% at the start of the century.

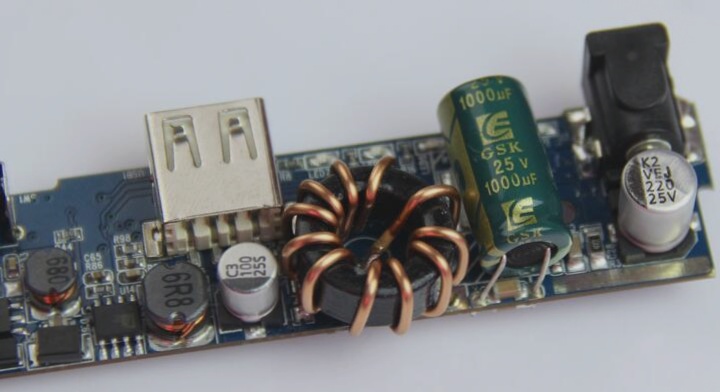

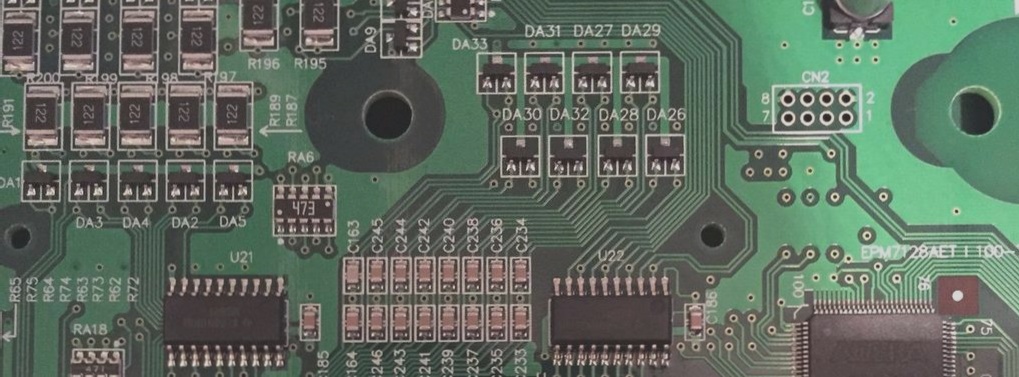

- Flexible Printed Circuit Boards (FPC) are addressing packaging and weight challenges as electronic product complexity grows.

- Laser cutting technology in FPC manufacturing eliminates the need for molds, reducing costs and improving precision.

- High-performance ultraviolet lasers ensure superior cutting results and prevent material damage in FPC production.

- FPC laser cutting is a non-contact method that eliminates stress-induced damage, unlike traditional contact-based techniques.

FPC Laser Cutting Process Advancements

- FPCs are vital in modern electronics, offering high wiring density, flexibility, and three-dimensional assembly capabilities.

- Laser cutting supplants traditional methods like die cutting, V-CUTs, and stamping due to its precision and stress-free processing.

- Non-contact FPC laser cutting machines deliver precise cutting, drilling, marking, welding, and scribing on various materials.

- FPCs allow bending, folding, and stretching without losing functionality, enabling innovative electronic system designs.

- Beyond Laser’s FPC cutting machine streamlines operations with automatic feeding, cutting, and material handling, reducing manual costs.

Advancements in Flexible Electronics and the Role of Laser Cutting Machines in PCB Manufacturing

Flexible electronic technology has led to the emergence of a wide range of electronic products. The utilization of flexible electronics is poised to create a trillion-yuan market and elevate the value of conventional industries. Laser cutting machines are set to be crucial in improving the processing capacities of FPC flexible circuit boards.

If you require PCB manufacturing services, feel free to get in touch with me. Contact me