The function of PCB solder mask film: The film serves to protect the circuit and glyphs by allowing the etching away of excess copper while preserving the necessary elements.

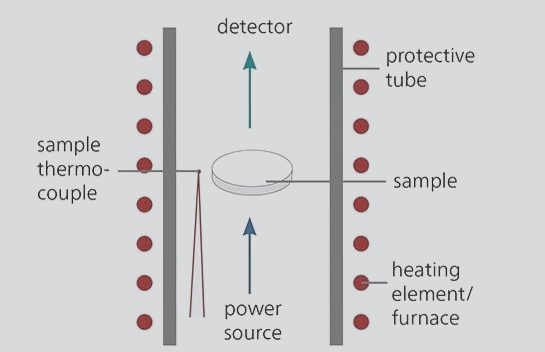

Practical application steps of PCB film: When creating a PCB circuit and solder mask, the PCB’s surface is first coated with a layer of photosensitive liquid and dried at 80 degrees Celsius. The film is then applied to the PCB board and exposed to an ultraviolet exposure machine before being removed. After this step, the excess liquid is removed, and the electric layer welding can be etched into the line. For the solder mask, the pads can be exposed.

What is the PCB solder mask color?

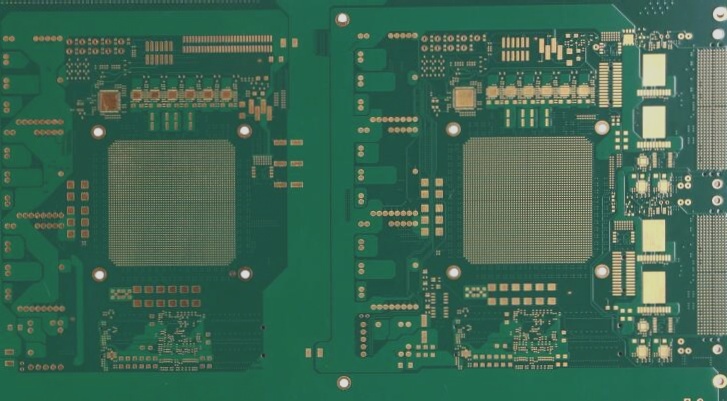

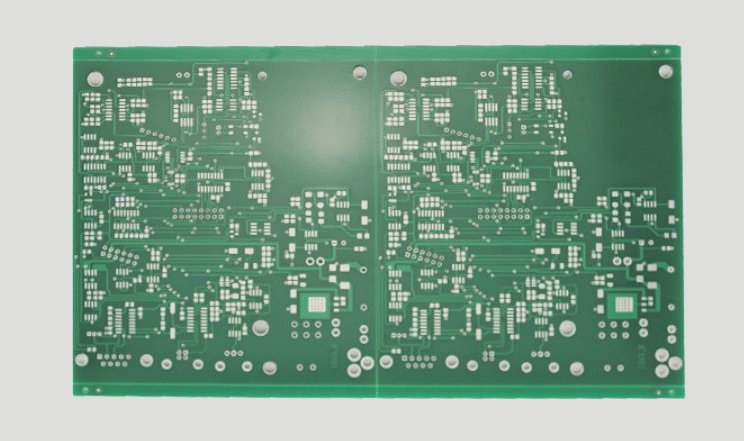

The term “PCB solder mask ink color” actually refers to the color of the PCB board itself. During PCB production, there are two ink processes: text printing and solder mask printing. Typically, upon receiving Gerber files from the customer for quoting, we also confirm essential details such as board thickness, copper thickness, process specifications, text color, solder mask color, and imposition. Based on this information, the final price for PCB fabrication is determined, including the color of the solder mask ink printed on the surface.

The most commonly used colors for PCB solder mask ink are green, followed by red, blue, black, white, purple, and others.

For printed circuit boards, the choice of solder mask ink color does not affect its functional performance. The primary functions of the solder mask are as follows:

1. Nickel-gold resistance: Many PCBs are nickel-gold plated, requiring good resistance to nickel-gold.

2. High light sensitivity: This ensures rapid curing of the ink during the curing process.

3. Cavitation resistance: Prevents bubble formation or pinholes during ink curing by spraying or printing.

4. Strong adhesion: Enhances ink durability, preventing peeling or warping.

5. Heat resistance: Protects PCB stability, especially for high-power components.

6. Halogen-free: Reflects environmentally conscious PCB manufacturing, focusing on lead-free and halogen-free processes.

7. Smoke concentration: Lower smoke emission during use reduces environmental impact.

PCB solder mask color

1. There are two types of printed PCB solder mask inks:

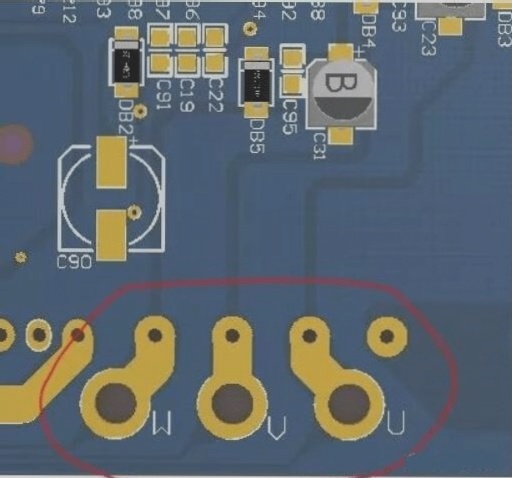

2. Liquid photosensitive ink: Liquid photosensitive ink is a special type of ink that can be applied to the entire board without the need for a printing plate. The ink coating can be cured by light exposure, and after development, it enables processing through etching, electroplating, electrophoresis, and coloring. This type of ink is suitable for small batch production, multiple varieties, personalized designs, and high-precision products.

3. UV solder mask ink: This type of ink is suitable for manufacturing the solder mask pattern on rigid printed circuit boards. It offers rapid curing under UV light, excellent heat resistance, strong adhesion, and meets the requirements for both single-sided and double-sided circuit boards. If the viscosity is very high, a small amount of special diluent can be added for thinning, but the amount should not exceed 5% of the ink volume.