The Truth About PCB Colors and Performance

Many people believe that the color of a motherboard’s PCB substrate is indicative of its quality and performance. However, the reality is that the color of the PCB does not directly impact its functionality. The color is determined by the solder resist, which plays a crucial role in preventing incorrect soldering and protecting components from oxidation and corrosion.

Common PCB Colors and Their Meanings

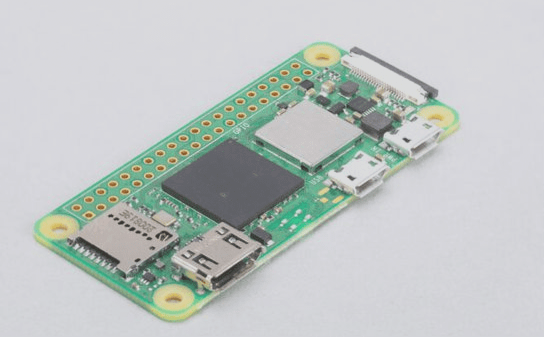

- Green: The most common color due to its maturity and simplicity in the manufacturing process.

- Red, Yellow, Blue, Black: Used for specific purposes, with each color possibly indicating different product grades or functions.

Advantages of Green PCBs

Green PCBs are the oldest, most cost-effective, and widely used option. The green color enhances instrument recognition during soldering processes and inspections, making it easier on the eyes for technicians.

Green vs. Other Colors

Colors like blue and black may introduce conductivity and increase the risk of short circuits. In contrast, green PCBs are environmentally friendly and do not emit toxic gases when exposed to high temperatures.

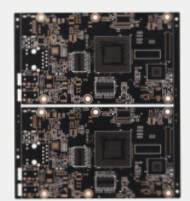

Challenges of Darker PCB Colors

Darker colors like black can complicate inspections and maintenance, leading to higher defect rates and difficulties in identifying circuit traces. Most manufacturers prefer green PCBs for their ease of maintenance and debugging.

Impact of Solder Mask Ink Color

While the color of the solder mask ink does not affect the final product, variations in shades of green can pose manufacturing challenges. Choosing the right color is crucial to avoid issues like visible plugs or bubbles during the production process.

Impact of Ink Color and Thickness on PCB Performance

- Ink color does not affect board performance, but ink thickness is crucial for impedance control.

- Gold-plated boards have strict thickness requirements for ink.

- Red ink is preferred for its cost, quality, and control over bubbles and thickness.

- Red ink conceals circuit blemishes better than green ink.

- Red and yellow inks provide more stable exposure in the imaging process.

- Green ink can be inconsistent, while white ink is the hardest to manage.

Importance of Strict Control in PCB Design

While PCB color is mainly a marketing consideration and does not impact performance, attention to detail in design and production processes is essential.

Users should not base motherboard purchasing decisions solely on PCB color.

If you have any PCB manufacturing needs, feel free to contact us.