Understanding PCB and PCBA in Electronics Manufacturing

1. What is a PCB?

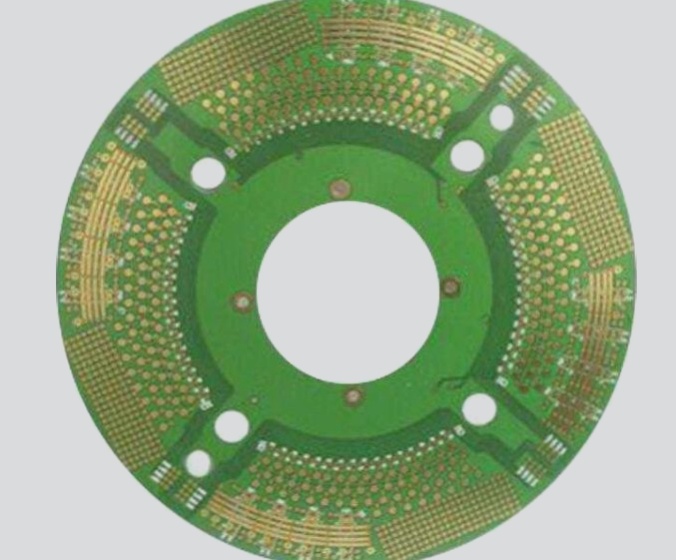

A PCB, or Printed Circuit Board, is a fundamental component in electronics, providing a platform for electronic parts and facilitating electrical connections.

2. The Evolution of PCBA

PCBA, which stands for Printed Circuit Board Assembly, involves populating a bare PCB using Surface Mount Technology (SMT) or the through-hole method known as Dual In-line Package (DIP).

3. PCB vs. PCBA

PCBA encompasses the entire assembly process of a PCB, including component integration, while PCB refers to the bare circuit board without components attached.

Key Points:

- PCB Production Process:

- – Manufacturer contact

- – Board opening

- – Drilling

- – Copper deposition

- – Artwork handling

- – Graphic plating

- – Film removal

- – Etching

- – Solder mask application

- – Surface finish (e.g., gold plating)

- – Forming

- – Testing

- – Final inspection

PCBs offer high density, reliability, planar structure, productivity, testability, ease of assembly, and maintainability.

Advancements in SMT and DIP:

SMT involves placing small electronic components directly onto the PCB surface, while DIP requires inserting component leads through pre-drilled holes. Both methods play crucial roles in modern electronics manufacturing.

Choosing the Right Supplier:

Electronic product planners must carefully select PCBA suppliers based on their expertise, quality standards, and production capabilities to ensure successful development and production.

Conclusion:

Understanding the differences between PCBs and PCBA is essential for anyone involved in electronics manufacturing, from design to production.