PCB Ink Characteristics

1. Stickiness and Thixotropy

When it comes to the manufacturing process of printed circuit boards (PCB), screen printing plays a crucial role. The ink used must have the right viscosity and thixotropy to ensure accurate image reproduction. Viscosity refers to the internal resistance of a liquid, while thixotropy is a unique property where viscosity decreases when stirred and returns to its original level when agitation stops.

2. Fineness

**Pigments and mineral fillers** are solid substances that need to be finely ground to a particle size of 4-5 microns to achieve the required ink fineness.

Precautions for Using PCB Ink

- Ensure ink temperature is maintained between 20-25°C to avoid viscosity issues.

- Thoroughly mix ink before use and seal the container immediately after.

- Use compatible cleaning agents for screen cleaning.

- Dry ink in a well-ventilated area with a good exhaust system.

- Conduct screen printing in a suitable environment meeting PCB manufacturing process requirements.

Causes and Countermeasures for Common PCB Ink Issues

1. Uneven Ink Application

Uneven ink application can occur due to various reasons such as insufficient mixing time, contamination, or poor-quality stencil material. Countermeasures include checking pre-treatment processes and confirming ink mixing parameters.

2. Copper Surface Cavitation

Copper surface cavitation, where ink separates from the surface, can be caused by poor pre-treatment processes. Ensuring proper pre-treatment steps are followed is essential to prevent this issue.

Common PCB Ink Issues and Solutions

- Adhesion of impurities to the board

- Copper surface depression

- Inadequate ink mixing

- Uneven ink thickness on the copper surface

- Impact damage to the ink surface

- Uneven oven temperature distribution, leading to underbaking or overbaking

- Repeated tin spraying or excessively high tin spraying temperatures

Countermeasures:

- Inspect the pre-treatment line to ensure each step meets quality standards.

- Verify the oven baking temperature and its heat distribution curve.

- Confirm ink mixing parameters.

- Review the production process to minimize external impacts.

- Check the tin spraying process parameters and conditions.

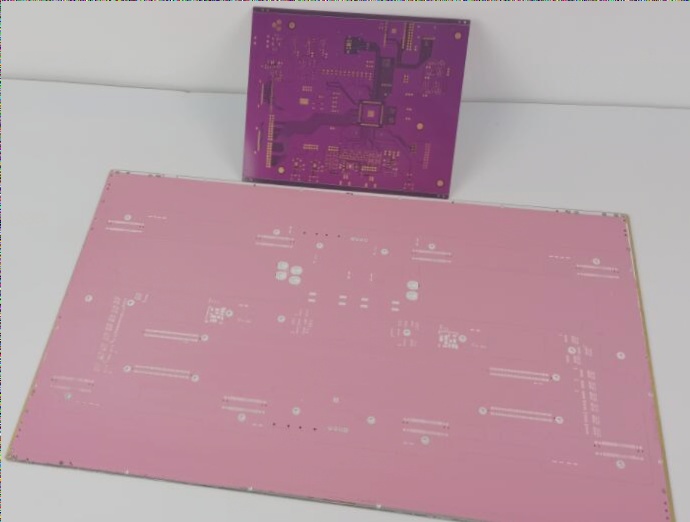

Ink Separation from Copper Surface

Ink separation from the copper surface can occur on large copper areas or at the corners of the circuit.

Possible Causes:

- Ink layer too thin

- Poor pre-treatment at line corners

- Insufficient baking

- Repeated tin spraying or excessively high tin spraying temperatures

- Extended flux soaking time

- Overly aggressive flux attack

- Ink damage at the corners

Countermeasures:

- Adjust the PCB solder mask printing thickness to ensure proper coverage.

If you have any PCB manufacturing needs, please do not hesitate to contact me.