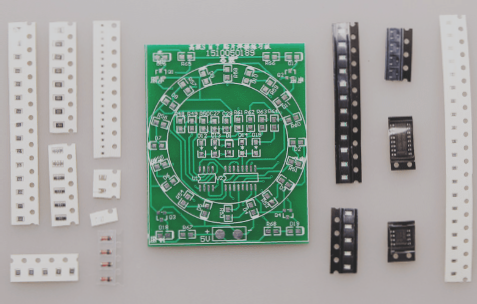

1. It is impossible to manufacture any number of printed circuit boards without encountering some problems, and often, some quality issues stem from the material of the copper clad laminate.

2. When quality problems arise in the manufacturing process, the substrate material frequently becomes the root cause of the issue.

3. Even a meticulously crafted and executed technical specification for laminates may not detail all the test items needed to determine if laminates are responsible for production problems.

4. Here are some of the most frequently encountered laminate issues and guidance on how to identify them.

5. When laminate problems arise, you should consider incorporating these issues into the laminate specifications.

6. Typically, if the technical specifications are not met, it results in ongoing quality fluctuations, which may ultimately lead to product scrapping.

7. Generally, material problems related to laminate quality emerge from different batches of raw materials used by manufacturers or from products manufactured under varying pressing loads.

2. When quality problems arise in the manufacturing process, the substrate material frequently becomes the root cause of the issue.

3. Even a meticulously crafted and executed technical specification for laminates may not detail all the test items needed to determine if laminates are responsible for production problems.

4. Here are some of the most frequently encountered laminate issues and guidance on how to identify them.

5. When laminate problems arise, you should consider incorporating these issues into the laminate specifications.

6. Typically, if the technical specifications are not met, it results in ongoing quality fluctuations, which may ultimately lead to product scrapping.

7. Generally, material problems related to laminate quality emerge from different batches of raw materials used by manufacturers or from products manufactured under varying pressing loads.