Challenges with Accelerometer Chip Yield in Consumer Product Testing

We are currently facing difficulties with the yield of a consumer product that integrates an accelerometer chip from ST. During testing, we are encountering failure rates of up to 40% due to the accelerometer readings falling outside of the specified range. The testing process involves checking for offsets along the X, Y, and Z axes, with our error margins exceeding the recommendations provided by the OEM. Adhering to their guidelines would result in even lower yield.

The failures seem to be isolated to the accelerometer chip itself. Interestingly, we have observed that by manually replacing the accelerometer on a failing board, the issue is resolved. Conversely, transferring an accelerometer chip from a failing board to a previously functional PCB results in the issue persisting.

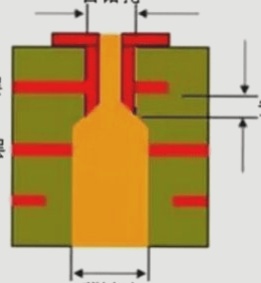

Our team has developed two main hypotheses to explain these issues. Firstly, we suspect that there may be an SMT-related issue causing stress on the accelerometer package, leading to the observed offsets. Secondly, we are considering the possibility that the depanelization process at the contract manufacturer (CM) could be causing damage. Our panels utilize mouse bites for separation, and individual boards are snapped out using a jig. It is plausible that the snapping action is generating excessive shock, potentially harming the MEMS chips.

Another consideration could be the quality of the parts supplied by ST. However, we are hesitant to attribute the issues solely to a faulty reel of components from the manufacturer.

If you have encountered similar challenges or have expertise in this area, we would appreciate insights on how to pinpoint the root cause of these issues.