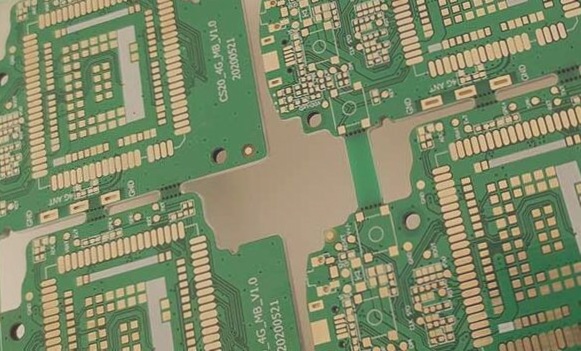

PCBA Processing First Article Inspection

During PCBA processing, the first piece inspection, also known as the first article inspection, is a critical step to ensure product quality and prevent defects in subsequent batches. This inspection plays a key role in managing product quality and maximizing economic benefits.

Data Requirements for First Inspection of PCBA Processing

- The production, engineering, and quality departments must verify the accuracy of information, including product drawings, process documents, BOM, PCBA components, and technical documents.

Key Node of First Inspection of PCBA Processing

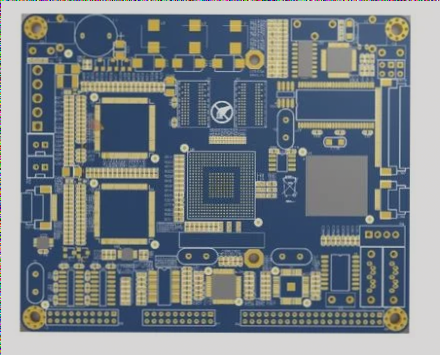

- The initial piece includes two panels: one for SMT modeling and one for functional testing to verify quality and consistency.

Matters Needing Attention in First Inspection of PCBA Processing

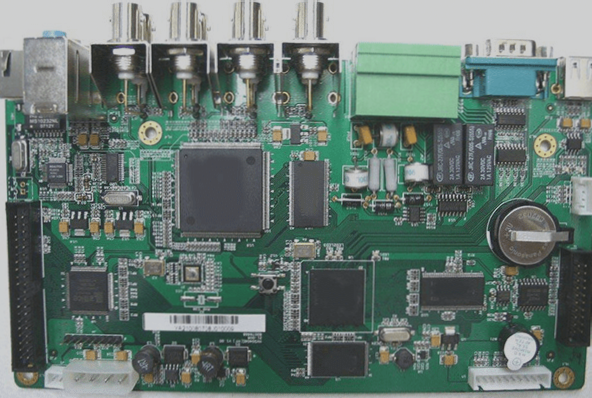

- Implement protective measures like electrostatic protection and verify component quality.

- Check component position, polarity, and soldering quality to meet technical document requirements.

First Inspection Mechanism of PCBA Processing

- Self-Inspection: Engineers check component orientation and placement.

- Mutual Inspection: Operators verify BOM and drawings for material shortages.

- Full Inspection: Quality inspectors conduct a comprehensive inspection using multimeters or ECR bridges to confirm product quality.

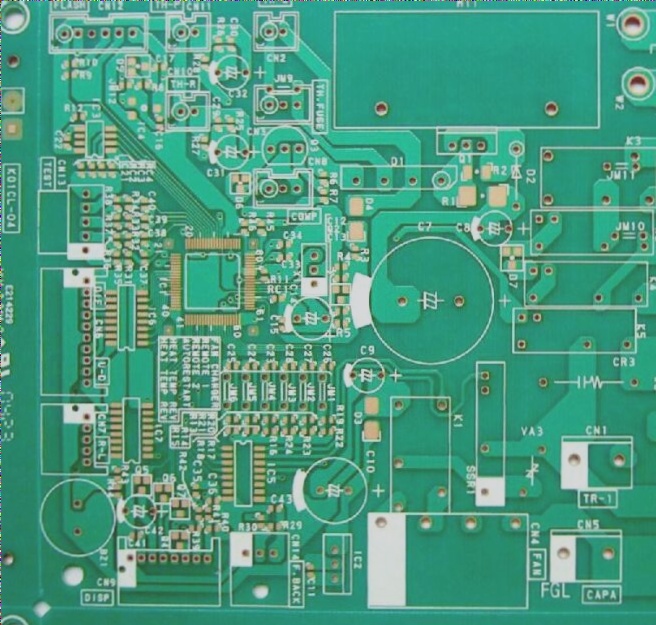

The Three-Inspection System in PCB Manufacturing

The three-inspection system in PCB manufacturing is based on the first piece, with the comparison standard being the sample and guidance documents agreed upon by the factory and the customer. The accuracy of the sample includes material correctness and welding accuracy. In cases where there is a discrepancy between customer guidance documents and samples, the documents take precedence. If no document is available, the sample prevails. This principle serves as protection for the foundry and responsibility for the customer, aiming to ensure and improve product quality and prevent quality losses due to errors by either party.

Latest Updates:

- Recent advancements in PCB technology have led to the development of more efficient and compact circuit designs.

- Industry experts are exploring the use of new materials to enhance the performance and durability of PCBs.

- Quality control measures in PCB manufacturing are continuously evolving to meet the demands of modern electronics.