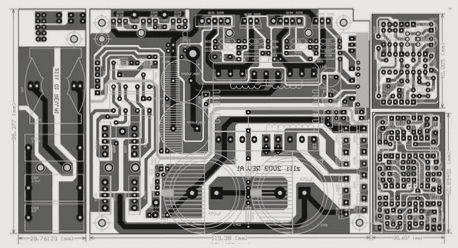

When a PCB board has completed the layout and routing design, and all connectivity and spacing checks are free of errors, is the PCB board truly finished? The answer is, of course, no. Many newcomers, as well as some seasoned engineers, often rush through or overlook final inspections due to time constraints, impatience, or overconfidence. This can lead to basic issues such as inadequate line width, component labels overlapping with vias, sockets placed too closely, and signal loops. Such errors can result in electrical or process problems, sometimes necessitating a complete reprint of the board, leading to waste. Therefore, after completing the layout and routing of a PCB board, a critical step is conducting thorough post-inspection.

There are numerous detailed aspects to consider during the inspection of PCB boards. Below are some of the fundamental elements that are particularly prone to error during this final review:

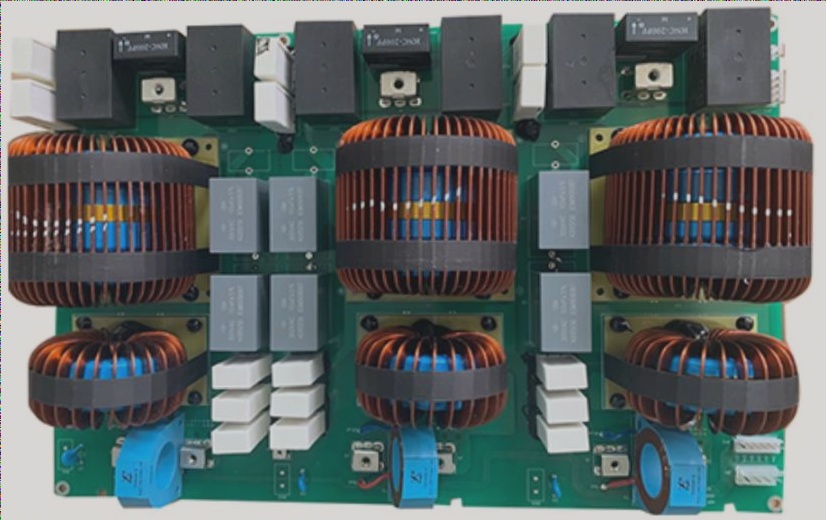

1. Component packaging

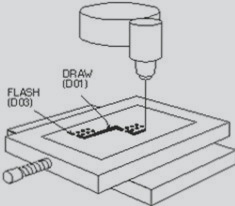

(1) Pad pitch. For new devices, it’s essential to create the component package yourself to ensure the spacing is correct. The pad spacing significantly impacts the soldering process of the components.

(2) Via size (if applicable). For plug-in devices, the vias should be sized with adequate margin, typically no less than 0.2mm for optimal performance.

(3) Contour silk screen. The silk screen outline for the device should exceed the actual dimensions to facilitate smooth installation.

2. Layout

(1) ICs should not be positioned near the edges of the board.

(2) Components within the same module circuit should be placed in close proximity. For instance, the decoupling capacitor should be near the IC’s power supply pin, and components forming a specific functional circuit should be grouped together with a clear hierarchy to ensure functionality.

(3) Arrange socket positions based on actual installation requirements. Sockets connect to other modules, so their placement should adhere to the principle of proximity, generally located near the edge of the board to ease installation.

(4) Be mindful of socket orientation. Sockets are directional; reversing their orientation necessitates a custom wire. For flat sockets, the orientation should point outward from the board.

(5) The Keep Out area must remain free of any devices.

(6) Sources of interference should be distanced from sensitive circuits. High-speed signals, rapid clocks, and high-current switching signals can create interference and should be kept away from sensitive circuits like reset and analog circuits, ideally separated by routing techniques.

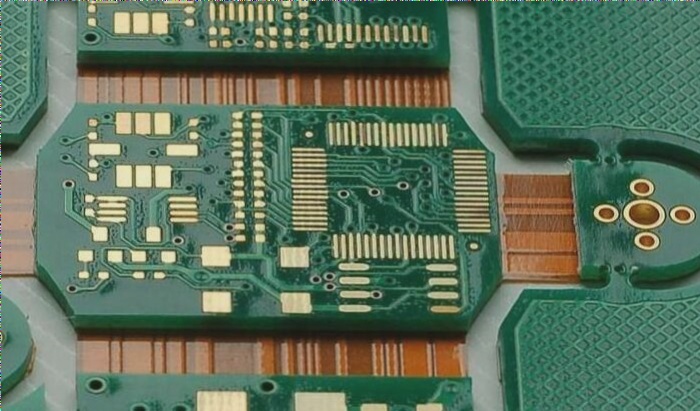

3. Wiring

(1) Line width size. The line width should be chosen based on both manufacturing capabilities and current-carrying capacity, with the minimum width not falling below the PCB manufacturer’s specifications. A typical guideline for current-carrying capacity is around 1mm/A.

(2) Differential signal lines. For differential cables such as USB and Ethernet, ensure that cables are of equal length, run parallel, and are on the same plane, with spacing determined by the required impedance.

(3) Consider the return path for high-speed lines. High-speed lines can cause electromagnetic radiation. A large area between the routing path and return path can create a single-turn coil that radiates interference. Therefore, it’s essential to keep the return path adjacent to the signal path. Multi-layer boards often include a power layer and ground plane to address this issue effectively.

(4) Be cautious with analog signal lines. Analog signal lines should be separated from digital signals and should avoid routing near interference sources (like clocks and DC-DC converters), with efforts made to keep wiring as short as possible.

There are numerous detailed aspects to consider during the inspection of PCB boards. Below are some of the fundamental elements that are particularly prone to error during this final review:

1. Component packaging

(1) Pad pitch. For new devices, it’s essential to create the component package yourself to ensure the spacing is correct. The pad spacing significantly impacts the soldering process of the components.

(2) Via size (if applicable). For plug-in devices, the vias should be sized with adequate margin, typically no less than 0.2mm for optimal performance.

(3) Contour silk screen. The silk screen outline for the device should exceed the actual dimensions to facilitate smooth installation.

2. Layout

(1) ICs should not be positioned near the edges of the board.

(2) Components within the same module circuit should be placed in close proximity. For instance, the decoupling capacitor should be near the IC’s power supply pin, and components forming a specific functional circuit should be grouped together with a clear hierarchy to ensure functionality.

(3) Arrange socket positions based on actual installation requirements. Sockets connect to other modules, so their placement should adhere to the principle of proximity, generally located near the edge of the board to ease installation.

(4) Be mindful of socket orientation. Sockets are directional; reversing their orientation necessitates a custom wire. For flat sockets, the orientation should point outward from the board.

(5) The Keep Out area must remain free of any devices.

(6) Sources of interference should be distanced from sensitive circuits. High-speed signals, rapid clocks, and high-current switching signals can create interference and should be kept away from sensitive circuits like reset and analog circuits, ideally separated by routing techniques.

3. Wiring

(1) Line width size. The line width should be chosen based on both manufacturing capabilities and current-carrying capacity, with the minimum width not falling below the PCB manufacturer’s specifications. A typical guideline for current-carrying capacity is around 1mm/A.

(2) Differential signal lines. For differential cables such as USB and Ethernet, ensure that cables are of equal length, run parallel, and are on the same plane, with spacing determined by the required impedance.

(3) Consider the return path for high-speed lines. High-speed lines can cause electromagnetic radiation. A large area between the routing path and return path can create a single-turn coil that radiates interference. Therefore, it’s essential to keep the return path adjacent to the signal path. Multi-layer boards often include a power layer and ground plane to address this issue effectively.

(4) Be cautious with analog signal lines. Analog signal lines should be separated from digital signals and should avoid routing near interference sources (like clocks and DC-DC converters), with efforts made to keep wiring as short as possible.