Enhancing PCB Quality Through Advanced Testing Methods

- If you aim for longevity in the industry, prioritizing excellent quality reigns supreme, and the PCB sector is no exception. Robust PCB testing protocols are imperative for ensuring product integrity.

- Conventional Testing Methods:

- Inspectors use magnifying glasses or calibrated microscopes for meticulous examination of circuit boards.

- Drawbacks include prolonged testing times, intermittent defect detection, and challenges in data collection.

- Challenges with Conventional Methods:

- As PCB production scales up, traditional testing methods become limited.

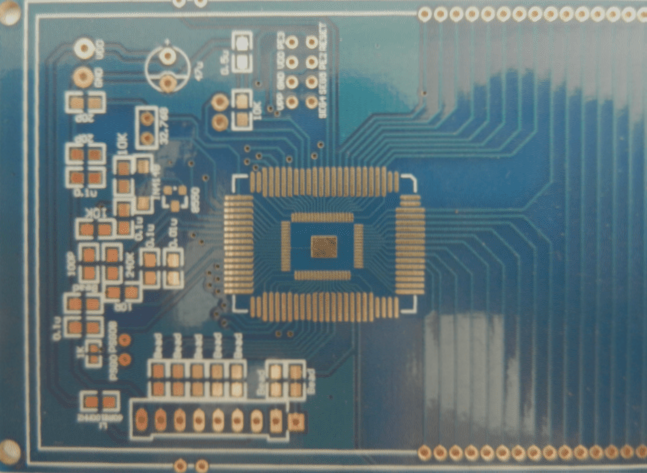

- Simple single-sided and complex double-sided multi-layer boards may have undetected issues.

- Enhanced Testing Approaches:

- Tests conducted after each production process for accurate defect detection.

- Bed-of-needle testers and flying probe testers commonly used for enhanced accuracy.

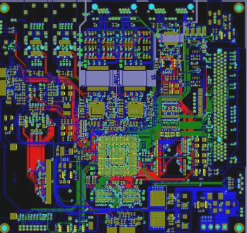

- Utilizing Cutting-Edge Technologies:

- Integration of image analysis and optical principles for resolving production challenges.

- Laser beam scanning during PCB fabrication enables comprehensive data collection for quality control.

- Improving Communication and Efficiency:

- Participate in test work promptly on the production line to avoid delays.

- Establish a quality department communication group for clear test requirements.

- Conduct regular internal training sessions for testers to maintain industry standards.

Advanced PCB Testing Fixtures for Quality Assurance

- PCB Test Fixtures Overview:

- Essential tool for detecting open and short circuits on PCB boards.

- Almost all PCBs undergo testing, with exceptions for simple single-sided panels.

- Testing Methods:

- Flying probe testing suitable for small batch samples.

- Test fixtures preferred by 98% of customers for larger batches due to efficiency.

- Cost Efficiency:

- Test fixtures incur a one-time cost, offering cost savings compared to flying probe tests.

- Recovery of test fixture costs possible with specific production volume thresholds.

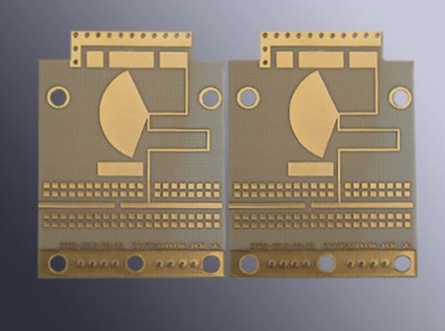

Materials for PCB Test Fixtures

When manufacturing PCB test fixtures, it is essential to have the following materials on hand: acrylic sheets, positioning columns, thimbles, cards, and leads. The selection of materials should be based on specific requirements to optimize production costs.

One effective way to reduce costs and standardize fixture production is to use reusable base templates. This approach not only saves money but also improves the overall quality of the fixtures.

Choosing the right test needles and related materials for test fixtures is crucial. It ensures that the testing process is of high quality and cost-effective.