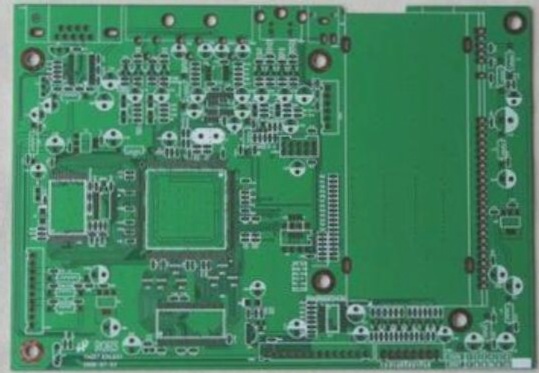

Understanding Printed Circuit Boards (PCBs)

- Printed Circuit Boards (PCBs) are essential components comprised of various elements and intricate manufacturing processes.

- PCBs can be single-layer, double-layer, or multi-layer, each with specific production techniques.

Components on a PCB

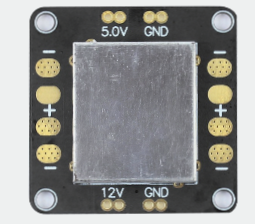

- Pad: Metal hole for soldering component pins

- Via: Metallic hole for inter-layer connections

- Mounting hole: Secures the PCB in place

- Wire: Copper film for electrical connections

- Connectors: Interconnect circuit boards

- Filling: Copper coating to reduce impedance

- Electrical boundary: Defines PCB size

Types of PCB Structures

- Single-layer board: Copper on one side for wiring and soldering

- Double-layer board: Copper on both sides for component placement and soldering

- Multi-layer board: Contains multiple operational layers for various functions

Working Layers on PCBs

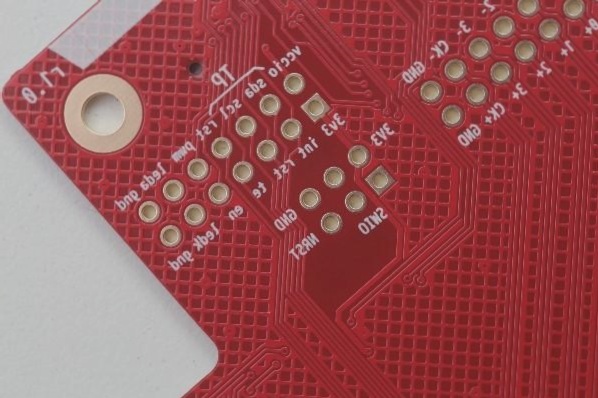

- Signal layer: For component placement and wiring

- Protective layer: Enhances operational reliability

- Silk screen layer: Prints essential information on the PCB

- Internal layer: Functions as a signal wiring layer

- Other layers: Include Drill Guide for drilling hole positions

Explore the intricate world of PCBs and their diverse applications to enhance your understanding of electronic components.