The Challenges of Test Point Allocation on Shrinking Circuit Boards

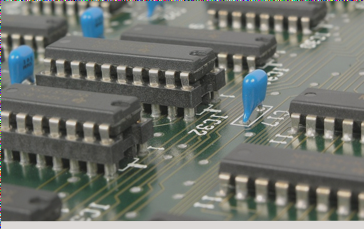

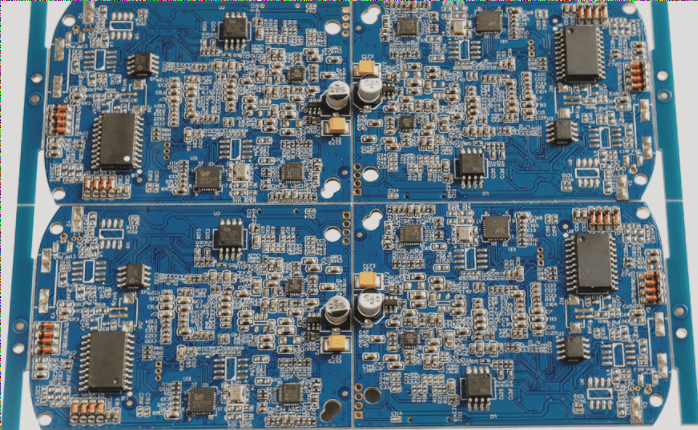

As technology advances, circuit boards are getting smaller, leading to difficulties in accommodating numerous electronic components on compact boards. This has made the allocation of space for test points a contentious issue between design and manufacturing teams. Test points, typically circular to match the probes, play a crucial role in facilitating easier production and enabling higher needle density on the bed.

Limitations of Needle Beds for Circuit Testing

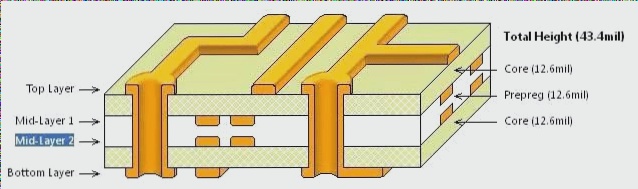

- Needle diameter poses a limitation, as excessively small diameters can lead to needle breakage and damage.

Constraints on Needle Spacing

- Needle spacing is constrained by the necessity for each needle to emerge from a hole and be soldered to a flat cable at its rear end. Inadequate spacing can result in contact short-circuits and interference from the flat cable.

Challenges with Needle Placement

- Placing needles near tall components can lead to collisions and potential damage. Tall components may also require holes in the needle bed base, posing challenges in accommodating test points for diverse components on PCBs.

Exploring Alternative Testing Techniques

- As boards shrink, discussions on reducing test points intensify. Current methods include Net test, Test Jet, Boundary Scan, JTAG, etc. Emerging techniques like AOI and X-Ray are being considered, but none fully replace ICT.

To ensure effective ICT needle implantation, consultation with fixture manufacturers on minimum test point diameter and adjacent point distance is crucial. Manufacturers typically specify desired and achievable minimum values, with large-scale manufacturers imposing constraints on the maximum distance between test points to prevent fixture damage.