The awareness of environmental protection in the field of industrial production of fr4 pcb is growing stronger. Domestic and foreign regulations have been formulated to clearly limit the use of toxic materials. Therefore, the development of green solder that can avoid pollution and replace traditional alloys has become one of the key issues facing the brazing industry. For example, many researchers at home and abroad have been working on the development of Lead-Free Solder and Cadmium-Free Solder. Simultaneously, the newly developed solder alloy should follow the principle of reducing cost and improving performance. For instance, the soft solder alloy used for chip soldering is developing towards high strength and high reliability, and the development principle is that the alloy does not contain precious metals, and its mechanical properties are between soft solder and gold-based solder.

The widespread use of Sn/Pb solder is due to its excellent performance and low cost. Pb-based solder is generally soft and can absorb the mechanical strain caused by the thermal expansion mismatch between the chip and the substrate. However, continuous mechanical stress (plus thermal cycle) can lead to strain accumulation at the grain boundary of the filler metal, resulting in microcracks, increased thermal resistance, and ultimately fatigue damage. Additionally, Pb and its compounds can have a carcinogenic effect after accumulating to a certain extent in the human body. Sn is often used as a filler metal base because it forms intermetallic compounds with various metals easily and has a low melting point. The wettability of solder based on Sn is better than that based on Pb. At the same time, Pb can improve the oxidation resistance of Sn-based solder and reduce the melting point of Sn-based solder.

Therefore, the matrix of highly reliable solder for SMT is mainly composed of Sn and Pb alloys. Currently, the main solder used for chips is Sn/Pb based materials. However, as electronic products continue to develop towards miniaturization, high density, and high performance, the size of solder joints is becoming smaller and smaller, while the thermal, electrical, and mechanical loads it bears are increasing. This requires the solder to have excellent fatigue and creep resistance. The traditional Sn/Pb solder has poor creep resistance, which does not meet the use requirements. There are also constant requirements for the properties of solder alloys in other fields, such as the need for composite solder in the automotive industry, the need for amorphous solder in the brazing of ceramics and metals, and the requirement for low melting point solder in heat-sensitive electronic components. Therefore, the development of green solder alloys with ideal performance and cost has become a research hotspot.

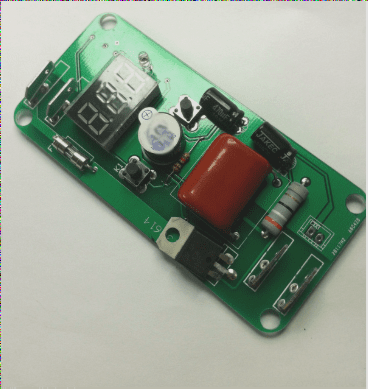

1. Application principle of zinc oxide varistor

Varistor is a voltage limiting protection device that utilizes the nonlinear characteristics of the varistor. When overvoltage occurs between the two poles of the varistor, it can clamp the voltage to a fixed value, providing protection for the subsequent circuit and enabling the PCBA board to have self-protection capability. The main parameters of the varistor include varistor voltage, current capacity, junction capacitance, and response time. The response time of the varistor is in nanoseconds, which is faster than air discharge tubes and slightly slower than TVS tubes. Generally, the response speed of the varistor used for overvoltage protection of electronic circuits meets the requirements. The junction capacitance of the varistor is generally in the range of hundreds to thousands of pF. When applied to the protection of AC circuits, its large junction capacitance can increase the leakage current, which needs to be considered when designing the protection circuit. The flow capacity of the varistor is larger than that of the gas discharge tube. The varistor is used in parallel with the protected electrical equipment or components to bear lightning overvoltage or transient operation overvoltage. Due to its fast response speed, the voltage at both ends of the varistor drops rapidly, protecting the equipment and components from the impact of overvoltage.

2. Selection of varistor voltage of zinc oxide varistor

Select the voltage V1mA under the specified current of the varistor according to the protected power supply voltage. The general selection principles are:

For DC circuits: V1mA ≥ 2.0VDC

For AC circuits: V1mA ≥ 2.2V effective value

The varistor voltage should be higher than the power supply voltage to protect the device and improve the varistor’s service life. Attention must also be paid to ensuring that the continuous working voltage will not exceed the allowable value and using higher nominal voltage varistors when poor grounding causes a rise in voltage between the line and ground.

3. Selection of flow rate

The flow rate given by the product is the current value it can withstand when conducting pulse tests according to the waveform, impact times, and gap time given by the product standard. The surge current absorbed by the varistor in practical applications should be less than the product’s flow rate.

The widespread use of Sn/Pb solder is due to its excellent performance and low cost. Pb-based solder is generally soft and can absorb the mechanical strain caused by the thermal expansion mismatch between the chip and the substrate. However, continuous mechanical stress (plus thermal cycle) can lead to strain accumulation at the grain boundary of the filler metal, resulting in microcracks, increased thermal resistance, and ultimately fatigue damage. Additionally, Pb and its compounds can have a carcinogenic effect after accumulating to a certain extent in the human body. Sn is often used as a filler metal base because it forms intermetallic compounds with various metals easily and has a low melting point. The wettability of solder based on Sn is better than that based on Pb. At the same time, Pb can improve the oxidation resistance of Sn-based solder and reduce the melting point of Sn-based solder.

Therefore, the matrix of highly reliable solder for SMT is mainly composed of Sn and Pb alloys. Currently, the main solder used for chips is Sn/Pb based materials. However, as electronic products continue to develop towards miniaturization, high density, and high performance, the size of solder joints is becoming smaller and smaller, while the thermal, electrical, and mechanical loads it bears are increasing. This requires the solder to have excellent fatigue and creep resistance. The traditional Sn/Pb solder has poor creep resistance, which does not meet the use requirements. There are also constant requirements for the properties of solder alloys in other fields, such as the need for composite solder in the automotive industry, the need for amorphous solder in the brazing of ceramics and metals, and the requirement for low melting point solder in heat-sensitive electronic components. Therefore, the development of green solder alloys with ideal performance and cost has become a research hotspot.

1. Application principle of zinc oxide varistor

Varistor is a voltage limiting protection device that utilizes the nonlinear characteristics of the varistor. When overvoltage occurs between the two poles of the varistor, it can clamp the voltage to a fixed value, providing protection for the subsequent circuit and enabling the PCBA board to have self-protection capability. The main parameters of the varistor include varistor voltage, current capacity, junction capacitance, and response time. The response time of the varistor is in nanoseconds, which is faster than air discharge tubes and slightly slower than TVS tubes. Generally, the response speed of the varistor used for overvoltage protection of electronic circuits meets the requirements. The junction capacitance of the varistor is generally in the range of hundreds to thousands of pF. When applied to the protection of AC circuits, its large junction capacitance can increase the leakage current, which needs to be considered when designing the protection circuit. The flow capacity of the varistor is larger than that of the gas discharge tube. The varistor is used in parallel with the protected electrical equipment or components to bear lightning overvoltage or transient operation overvoltage. Due to its fast response speed, the voltage at both ends of the varistor drops rapidly, protecting the equipment and components from the impact of overvoltage.

2. Selection of varistor voltage of zinc oxide varistor

Select the voltage V1mA under the specified current of the varistor according to the protected power supply voltage. The general selection principles are:

For DC circuits: V1mA ≥ 2.0VDC

For AC circuits: V1mA ≥ 2.2V effective value

The varistor voltage should be higher than the power supply voltage to protect the device and improve the varistor’s service life. Attention must also be paid to ensuring that the continuous working voltage will not exceed the allowable value and using higher nominal voltage varistors when poor grounding causes a rise in voltage between the line and ground.

3. Selection of flow rate

The flow rate given by the product is the current value it can withstand when conducting pulse tests according to the waveform, impact times, and gap time given by the product standard. The surge current absorbed by the varistor in practical applications should be less than the product’s flow rate.