Effective PCB Wiring Tips for Optimal Performance

Understanding PCB Wiring Essentials

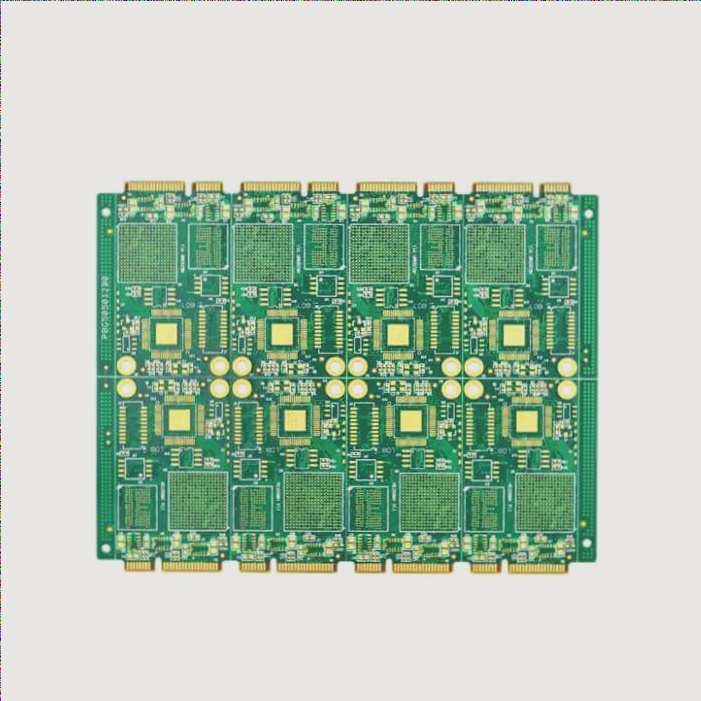

- PCB boards come in single-layer, double-layer, and multi-layer configurations.

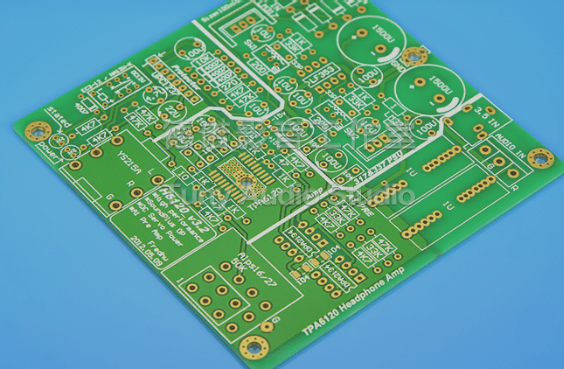

- Double-layer boards are commonly used in audio systems, with various via hole options.

Manual routing before automatic routing is crucial for high-quality lines. Ground wire isolation and perpendicular layer wiring reduce interference. Automatic routing effectiveness relies on well-set routing rules.

Layout Best Practices

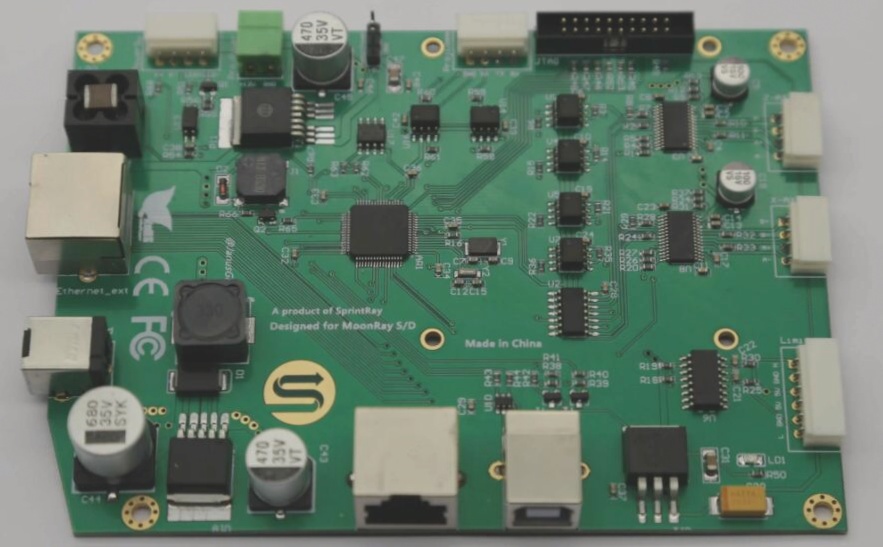

- Separate digital and analog circuits to minimize interference.

- Avoid mixing low-speed and high-speed signals.

Precautions for Power Supply and Ground Wiring

- Include a decoupling capacitor between power supply and ground for noise reduction.

- Widen ground wires more than power wires for optimal performance.

- Utilize large copper areas as ground wires for improved stability.

Mixed Digital and Analog Circuits Handling

Separate digital and analog grounds to prevent interference. Keep high-frequency signals away from sensitive analog components.

Optimizing Line Corners

Optimizing PCB Design for Signal Integrity

Changes in wire thickness at corners can lead to reflections in PCBs. To minimize this effect, it is recommended to avoid right angles and opt for 45-degree angles or rounded corners. While rounded corners offer the best performance, they are more intricate to implement, making 45-degree angles a practical choice for most signals, except for highly sensitive lines.

Key Steps for Ensuring PCB Design Quality

After completing the wiring process, it is crucial to conduct a thorough check to guarantee a high-quality PCB design. Similar to reviewing exam answers, inspecting the following aspects is vital:

- Verify the distances between wires, component pads, and through holes to meet production requirements.

- Ensure appropriate widths and coupling of power and ground lines for low wave impedance.

- Properly manage key signal lines by keeping their lengths short and separating input and output lines.

- Implement separate ground wires for analog and digital circuits.

- Prevent signal short circuits caused by added graphics on the PCB.

- Adjust any unsatisfactory line shapes.

- Check for proper process lines, solder mask size, and correct placement of text labels on device pads.

- Reduce the edge of the power ground layer in multi-layer boards to avoid short circuits.

These practices, honed through experience, play a critical role in effective PCB design. In addition to mastering design tools, a strong theoretical foundation and practical know-how are essential. Attention to detail during the design phase is paramount, as even minor errors can impact the final product’s usability. Investing extra time in meticulous checking during the drawing process can prevent more time-consuming issues down the line.