1. What are the skills of high-frequency circuit PCB design?

Designing high-frequency PCBs is a complex process, where numerous factors can directly affect the performance of the circuit. Both the design and routing of high-frequency circuits are crucial to the overall functionality. Here are ten essential tips for high-frequency circuit PCB design:

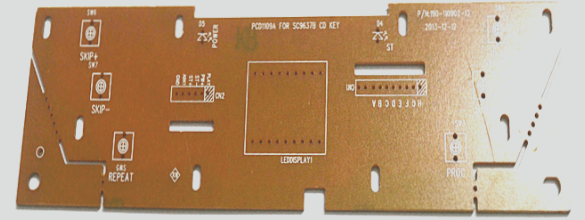

1. Multilayer PCB board wiring

High-frequency circuits often require high integration and dense routing. Multi-layer boards are essential not only for routing but also as an effective means to minimize interference. During the PCB layout stage, selecting an appropriate board size with a sufficient number of layers allows for optimal use of intermediate layers for shielding, improving grounding, reducing parasitic inductance, and shortening signal transmission paths. These methods enhance the reliability of high-frequency circuits, including minimizing signal cross-interference. Data suggests that, when using the same material, a four-layer board can exhibit noise levels 20dB lower than a double-sided board. However, more layers mean a more complex manufacturing process and higher costs, so choosing the right number of layers is crucial. Proper component layout planning and adherence to correct routing rules are essential for effective design.

2. Minimize lead bends between the pins of high-speed electronic devices

1. For high-frequency circuit wiring, use straight lines wherever possible. If turns are necessary, use 45-degree angles or circular arcs. This practice enhances copper foil strength in low-frequency circuits and minimizes external emissions and mutual coupling of high-frequency signals.

2. The lead length between high-frequency circuit device pins should be minimized. Signal radiation intensity is proportional to trace length, so shorter leads reduce coupling to nearby components. High-frequency signal lines like clock, crystal oscillator, DDR data, LVDS, USB, and HDMI should be kept as short as possible.

3. Minimize the number of vias between high-frequency circuit device pins. Fewer vias reduce distributed capacitance (about 0.5pF per via), which increases speed and decreases data error potential.

4. PCB Layout Considerations:

– **PCB Routing**: Keep printed wire layouts as short as possible, especially for high-frequency circuits. Use rounded bends instead of sharp corners to avoid affecting electrical performance. Ensure wires on both sides of a two-layer PCB are perpendicular or angled to reduce parasitic coupling. Avoid using printed wires as input/output connections whenever possible; add a ground wire between such connections to prevent feedback.

– **Width of Printed Wire**: Wire width should meet electrical performance requirements and be suitable for production. The minimum width is determined by current capacity and should not be less than 0.2mm. In high-density, high-precision circuits, wire width and spacing are usually 0.3mm. For currents around 2A, a wire width of 1 to 1.5mm is generally sufficient to avoid significant temperature rise. Common ground wires should be as thick as possible, preferably 2 to 3mm, to maintain stable microprocessor timing signals and reduce noise margin degradation. For DIP package IC pin routing, follow the 10-10 and 12-12 principles: for two wires between pins, use 50mil pad diameter with 10mil width and spacing; for one wire, use a 64mil pad with 12mil width and spacing.

Designing high-frequency PCBs is a complex process, where numerous factors can directly affect the performance of the circuit. Both the design and routing of high-frequency circuits are crucial to the overall functionality. Here are ten essential tips for high-frequency circuit PCB design:

1. Multilayer PCB board wiring

High-frequency circuits often require high integration and dense routing. Multi-layer boards are essential not only for routing but also as an effective means to minimize interference. During the PCB layout stage, selecting an appropriate board size with a sufficient number of layers allows for optimal use of intermediate layers for shielding, improving grounding, reducing parasitic inductance, and shortening signal transmission paths. These methods enhance the reliability of high-frequency circuits, including minimizing signal cross-interference. Data suggests that, when using the same material, a four-layer board can exhibit noise levels 20dB lower than a double-sided board. However, more layers mean a more complex manufacturing process and higher costs, so choosing the right number of layers is crucial. Proper component layout planning and adherence to correct routing rules are essential for effective design.

2. Minimize lead bends between the pins of high-speed electronic devices

1. For high-frequency circuit wiring, use straight lines wherever possible. If turns are necessary, use 45-degree angles or circular arcs. This practice enhances copper foil strength in low-frequency circuits and minimizes external emissions and mutual coupling of high-frequency signals.

2. The lead length between high-frequency circuit device pins should be minimized. Signal radiation intensity is proportional to trace length, so shorter leads reduce coupling to nearby components. High-frequency signal lines like clock, crystal oscillator, DDR data, LVDS, USB, and HDMI should be kept as short as possible.

3. Minimize the number of vias between high-frequency circuit device pins. Fewer vias reduce distributed capacitance (about 0.5pF per via), which increases speed and decreases data error potential.

4. PCB Layout Considerations:

– **PCB Routing**: Keep printed wire layouts as short as possible, especially for high-frequency circuits. Use rounded bends instead of sharp corners to avoid affecting electrical performance. Ensure wires on both sides of a two-layer PCB are perpendicular or angled to reduce parasitic coupling. Avoid using printed wires as input/output connections whenever possible; add a ground wire between such connections to prevent feedback.

– **Width of Printed Wire**: Wire width should meet electrical performance requirements and be suitable for production. The minimum width is determined by current capacity and should not be less than 0.2mm. In high-density, high-precision circuits, wire width and spacing are usually 0.3mm. For currents around 2A, a wire width of 1 to 1.5mm is generally sufficient to avoid significant temperature rise. Common ground wires should be as thick as possible, preferably 2 to 3mm, to maintain stable microprocessor timing signals and reduce noise margin degradation. For DIP package IC pin routing, follow the 10-10 and 12-12 principles: for two wires between pins, use 50mil pad diameter with 10mil width and spacing; for one wire, use a 64mil pad with 12mil width and spacing.