The Importance of PCB Design in High-Speed Signal Integrity

When it comes to PCB design, defining a clear purpose is essential. Critical signal lines demand strict adherence to standards for wiring length and ground loop management. On the other hand, low-speed or less crucial signal lines can have a slightly lower wiring priority.

Key considerations in PCB design include power supply segmentation, memory clock line requirements, control lines, data line lengths, and high-speed differential line routing. In Project A, the use of a memory chip to implement 1G DDR memory underscores the importance of precise routing for this component.

It is crucial to consider the topological arrangement of control and address lines, manage length disparities between data and clock lines, and more. Specific wiring guidelines can be established based on the chip’s data sheet and actual operating frequency.

For example, ensuring that the length of data lines within the same group does not exceed a specified number of mils and limiting the length difference between channels to a certain number of mils are vital aspects of the design process.

By clearly outlining all critical wiring specifications in the design, they can be translated into overall wiring constraints, allowing for the use of automated routing tools in CAD software for PCB design. This approach is increasingly gaining traction in high-speed PCB development.

Latest Trends in PCB Fabrication

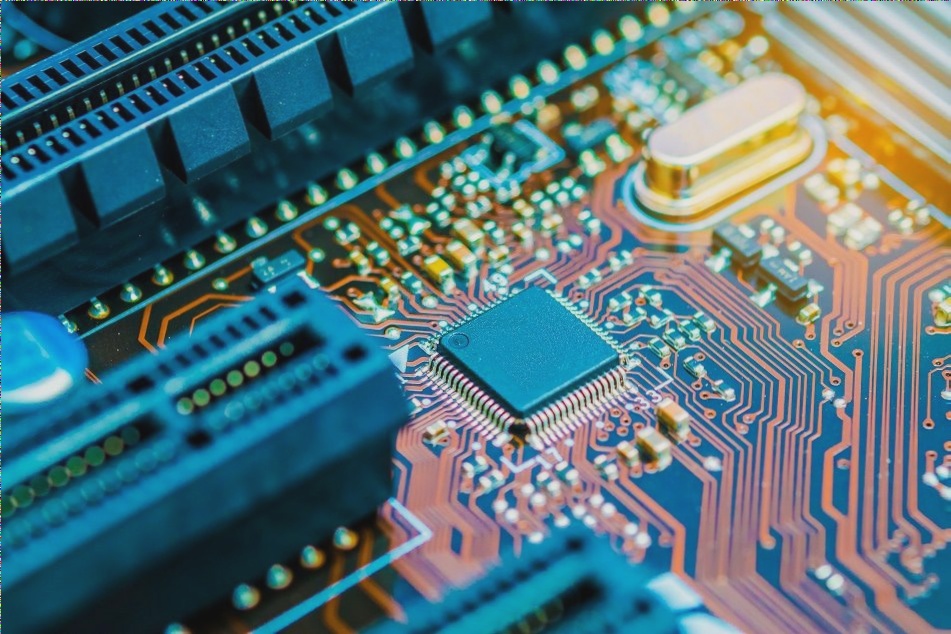

With advancements in technology, PCB designers are now focusing on implementing advanced fabrication techniques to meet the demands of high-speed signal integrity. Factors such as impedance control, signal integrity analysis, and thermal management are gaining prominence in modern PCB fabrication processes.

Moreover, the integration of advanced materials like high-speed laminates and copper foils with improved signal transmission capabilities is revolutionizing the PCB fabrication industry. These materials enhance signal integrity, reduce crosstalk, and improve overall performance in high-speed electronic devices.

By staying updated on the latest trends and innovations in PCB fabrication, designers can ensure the optimal performance and reliability of electronic products in today’s fast-paced technological landscape.