The Significance of PCB Design in Modern Electronics

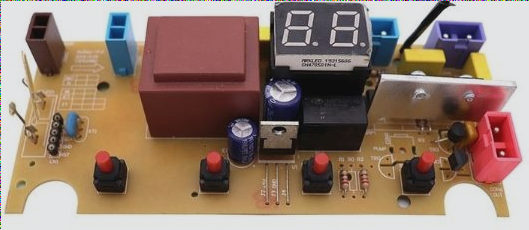

The PCB, also known as the Printed Circuit Board, is a crucial component that serves as the foundation for electronic circuits in today’s technology-driven world. PCBs are utilized in a wide range of electronic devices, making them virtually ubiquitous.

A Story Highlighting the Importance of PCB Design

Let me share a compelling story that underscores the critical role of PCB design in electronic manufacturing. This tale revolves around a company that produced innovative telephones, featuring advanced functions like hands-free capabilities.

An Unexpected Malfunction

One fateful night, a new push-button telephone with hands-free functionality experienced a mysterious malfunction, causing the phone to buzz and beep incessantly. After a thorough investigation, it was revealed that the poor PCB design had inadvertently triggered the hands-free function, leading to a disruptive false alarm. This incident resulted in significant economic losses for the company, prompting a redesign of the hands-free feature using mechanical buttons.

Lessons from Experienced Engineers

- Experienced engineers from the past demonstrated remarkable skill in PCB design, creating intricate circuit layouts with minimal jumpers and crossovers using only pencils and graph paper.

- There is much to learn from these pioneers, including the art of component arrangement for efficient routing and optimizing board space under dual in-line ICs.

PCB Design as an Art Form

Beyond its technical aspects, PCB design is considered an art form that requires continuous refinement of skills and aesthetic sensibilities. Engineers are encouraged to enhance their abilities and strive for excellence in their craft.

Optimizing PCB Design for Unique Products

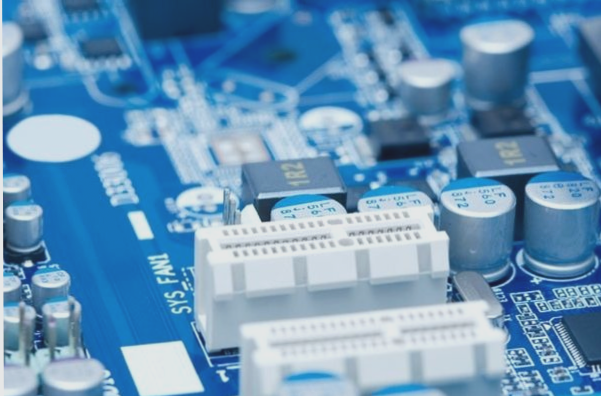

When utilizing design software like PROTEL for PCB layout and routing, automated solutions may not always cater to the specific requirements of each product. While these tools focus on general aspects of design, creating a truly optimized layout demands a deep understanding of the product’s individual needs. Designing a PCB involves crafting a customized solution tailored to the product.

Challenges Faced in PCB Design

During a project involving a PCI board design with a chip requiring a dual-layer layout and 160 connections, the complexity of PCB design became evident. Without relying on automatic routing, ensuring proper connections while minimizing interference and adhering to wiring length specifications posed a significant challenge. This experience highlighted the intricacies of PCB design and the importance of expertise in the field.

The Art of PCB Design

PCB design goes beyond mere electrical connections; it encompasses circuit knowledge, production processes, and aesthetic considerations. Many view PCB design as an art form that requires a comprehensive understanding of various elements. Recognizing the value of skilled PCB design is essential, especially when cost-saving measures are a priority.

Importance of Efficient Routing

Even with a well-developed initial plan, poor routing design can lead to a host of issues such as circuit oscillation, signal interference, inadequate signal separation, and potential damage to high-power amplifier circuits. The repercussions of subpar design can be severe and may result in unforeseen complications.