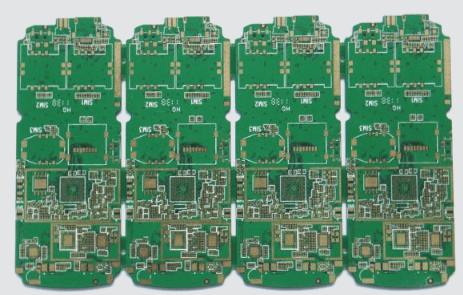

The complexity of PCB expedited prototyping depends on the number of layers and the number of vias on each layer. This determines the changes in the layers where vias start and stop, requiring more lamination and drilling steps in the PCB manufacturing process. The lamination process defined by manufacturers involves using heat and pressure to press two copper layers and a dielectric between adjacent copper layers to create a multilayer PCB laminate.

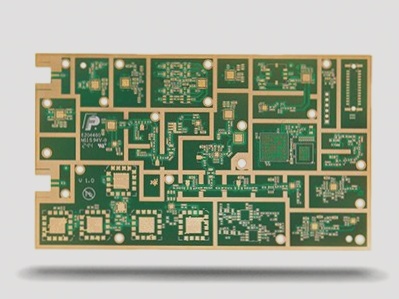

Manufacturers, such as PCB expedited prototyping, optimize the through-hole structure by utilizing micro-via and high-density integration (HDI) technology. HDI technology not only reduces costs by decreasing the number of layers but also makes the PCB smaller, lighter, and thinner while enhancing electrical performance.

The material selection for PCB expedited prototyping depends on various application-based factors, specifically the frequency, operating speed, and maximum temperature. These factors include thermal stability, temperature-related reliability, temperature cycle reliability, heat transfer rate, delamination time, and more. The choice of materials becomes more crucial with higher operating frequencies or signal speeds. For instance, using polyimide instead of conventional phenolic FR-4 materials may increase costs by 3-5 times, while opting for PTFE-based microwave materials could result in a cost increase of up to 10-50 times.

WellCircuits Limited specializes in manufacturing high-precision double-sided, multi-sided, impedance, blind-buried vias, and thick copper circuit boards. Their product range includes HDI, thick copper, backplanes, rigid-flex combinations, buried capacitance, and buried resistance. They offer various circuit board types like Golden Finger to meet diverse customer requirements.

Manufacturers, such as PCB expedited prototyping, optimize the through-hole structure by utilizing micro-via and high-density integration (HDI) technology. HDI technology not only reduces costs by decreasing the number of layers but also makes the PCB smaller, lighter, and thinner while enhancing electrical performance.

The material selection for PCB expedited prototyping depends on various application-based factors, specifically the frequency, operating speed, and maximum temperature. These factors include thermal stability, temperature-related reliability, temperature cycle reliability, heat transfer rate, delamination time, and more. The choice of materials becomes more crucial with higher operating frequencies or signal speeds. For instance, using polyimide instead of conventional phenolic FR-4 materials may increase costs by 3-5 times, while opting for PTFE-based microwave materials could result in a cost increase of up to 10-50 times.

WellCircuits Limited specializes in manufacturing high-precision double-sided, multi-sided, impedance, blind-buried vias, and thick copper circuit boards. Their product range includes HDI, thick copper, backplanes, rigid-flex combinations, buried capacitance, and buried resistance. They offer various circuit board types like Golden Finger to meet diverse customer requirements.