The Importance of Neat and Clear PCB Schematic Diagrams

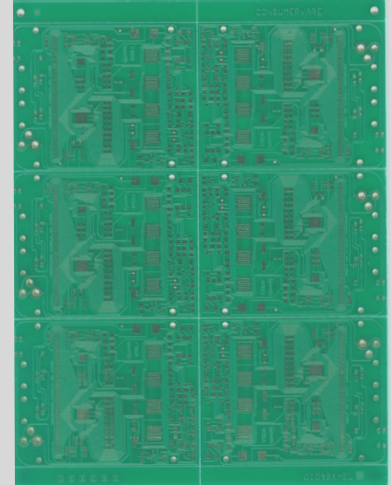

Creating a PCB schematic diagram that is neat and well-organized is crucial for easy readability and understanding. The design should adhere to national standards to ensure accuracy and clarity.

Key Points for Designing PCB Schematic Diagrams:

- Ensure clear characters, thick lines, and clear subdivisions for easy readability.

- Plan the layout in advance to position graphic symbols uniformly.

- Label each component with a position symbol consisting of text symbols and footnote serial numbers.

- Use position sequence numbers like R1, R2, R3 for resistors and C1, C2, C3 for capacitors.

- Include component details such as number, code, name, model, and quantity in a component list.

- Classify components and follow the sequence numbers for easy assembly.

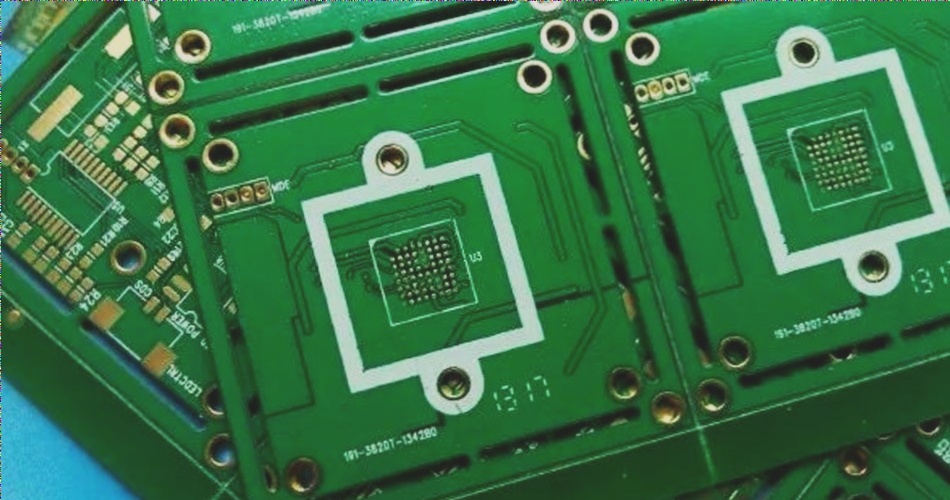

WellCircuits Limited: Your PCB Manufacturing Partner

WellCircuits Limited specializes in manufacturing high-precision PCBs to meet various customer requirements:

- Double-sided and multi-layer PCBs

- Impedance-controlled PCBs

- Blind/buried via PCBs

- Thick copper PCBs

- HDI PCBs

- Backplanes and rigid-flex combinations

- Buried capacitance and resistance PCBs

- Golden Finger PCBs

Trust WellCircuits Limited for all your PCB manufacturing needs.