Main Features of Electronic Assembly and Processing

- Electronic products are technology-intensive and require various basic techniques for assembly, including component screening, lead forming, wire processing, welding, installation, and quality inspection.

- Quantitative analysis of assembly quality is challenging, often relying on visual inspection for welding quality and tactile assessment for components like dials and knobs. It is essential to follow correct installation methods to avoid errors.

- Personnel involved in assembly work undergo rigorous training and selection processes. Certification is required to ensure high technical competence and prevent the production of defective products.

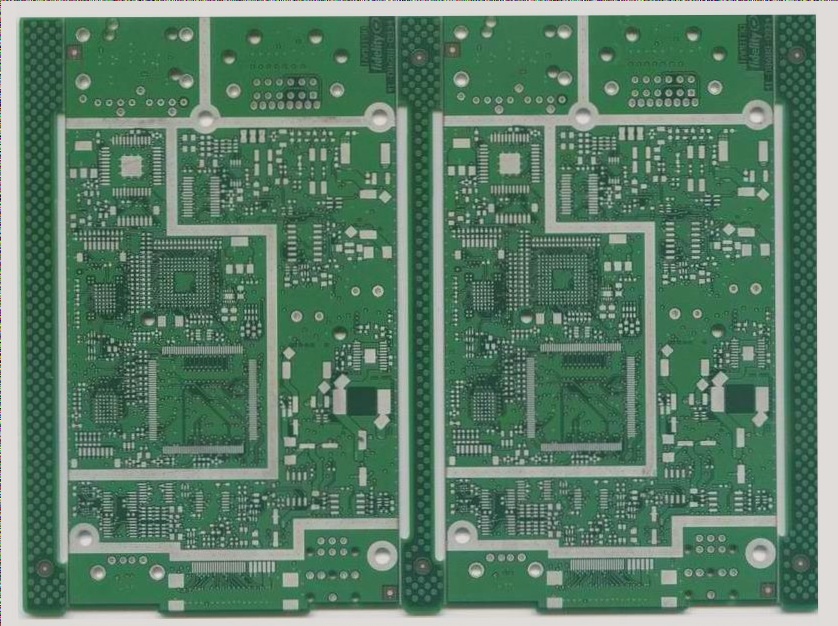

Latest Updates in PCB Assembly

With the advancement of technology, PCB assembly processes have evolved to incorporate more automation and precision. Modern PCB manufacturing facilities utilize state-of-the-art equipment for soldering, component placement, and quality control. Additionally, the use of artificial intelligence and machine learning algorithms has improved defect detection and overall production efficiency.

Future Trends in Electronic Assembly

The future of electronic assembly is moving towards miniaturization and integration. Manufacturers are focusing on developing smaller, more efficient electronic components and exploring innovative assembly techniques such as 3D printing and flexible electronics. These advancements aim to enhance product performance, reduce production costs, and meet the growing demand for compact and multifunctional electronic devices.