Effective PCB Static Control Program

- Design PCBs with Electrostatic Protection

- Minimize Materials and Processes Generating Static Electricity

- Safe Dissipation of Electrostatic Discharge

- Prevent Electrostatic Discharge Impact

- Ground or shunt components and assemblies properly to disperse discharge.

- Transport sensitive elements and packaging in suitable materials to shield products from static electricity.

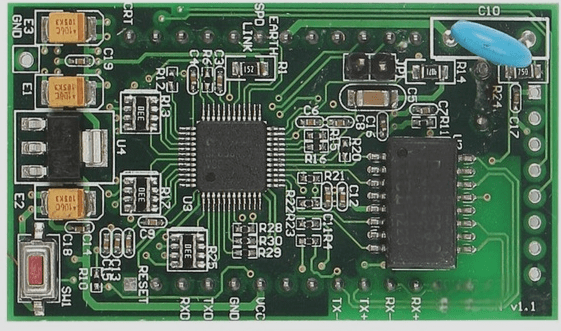

When designing PCBs, it is crucial to consider electrostatic protection for components and products. Opt for components that are not sensitive to PCB static electricity or utilize ESD-sensitive components for proper input protection. The incorporation of ESD control in product design reduces the occurrence of issues.

Efforts should be made to reduce or eliminate materials and processes that generate PCB static electricity. Maintaining consistent or zero potential between materials helps prevent ESD. Connecting dissipating or conductive materials to a common ground reduces the generation and accumulation of discharge.

Conductive and grounded materials play a crucial role in safely dissipating or neutralizing PCB electrostatic discharge. Ions can be utilized to neutralize discharge on insulating materials.

Measurement for Effective Protection

Measurement is a reliable method for identifying and quantifying areas requiring PCB electrostatic protection. This enables a focus on critical areas, avoiding unnecessary costs.

WellCircuits Limited: Your PCB Expert

WellCircuits Limited specializes in manufacturing high-precision double-sided, multi-layer, impedance-controlled, blind buried vias, and thick copper circuit boards. Their diverse product range caters to various customer needs for product development and business collaboration.

For more information, visit WellCircuits.