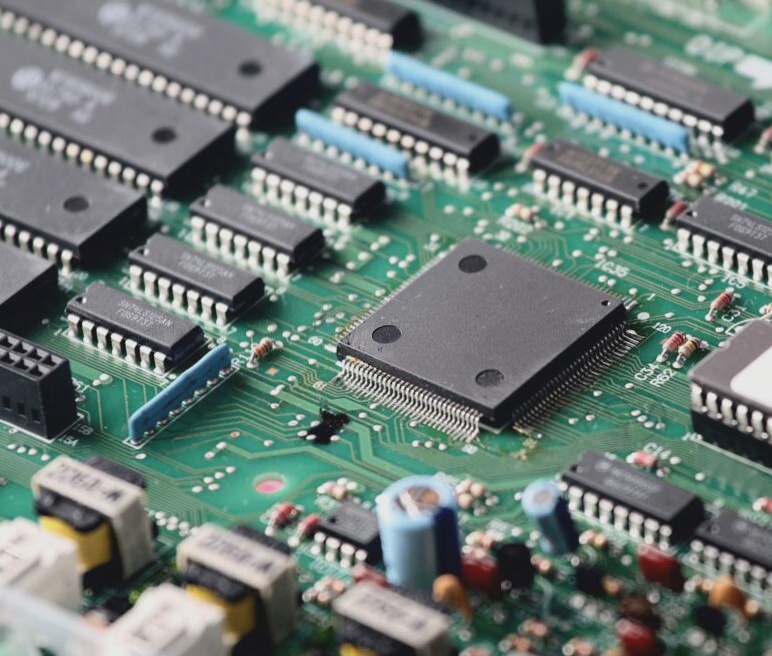

SMT Patch Processing in PCBA Plants

Preparation Work for Efficient Production

- Thorough pre-production preparations are crucial for smooth SMT patch processing in PCBA plants.

- Standardized production process management is essential for timely completion.

- Engineering tasks include planned order arrangements, material checks, and sample completion.

Production Steps

- SMT Patch Processing:

- Confirm material readiness and tools 2 hours before production.

- Coordinate for supplementary materials if needed.

- Inspect pieces for defects and address issues promptly.

- DIP Plug-In Processing:

- Schedule material preparation and confirm quality.

- Determine auxiliary materials in advance.

- Conduct pre-production meetings for each product.

Quality Assurance

- IPQC inspections and quality confirmations are critical for both SMT and DIP processes.

- Adherence to planned orders and timely quality checks are emphasized.

Process Optimization

- Streamlined production and testing processes for new and return orders.

- Integration of SMT and DIP processes for efficient assembly.

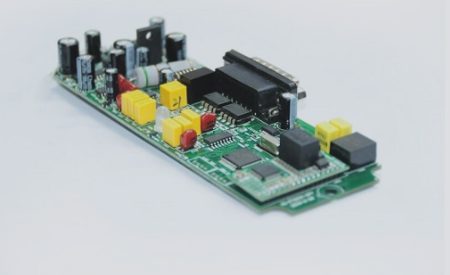

Key Elements in SMT Patch Processing

SMT patch processing involves essential steps in PCB technology:

- Silk Screen (Glue Dispensing): Application of solder paste or glue on PCB pads.

- Dispensing: Fixing components onto the PCB using specialized equipment.

PCB Manufacturing Process Steps:

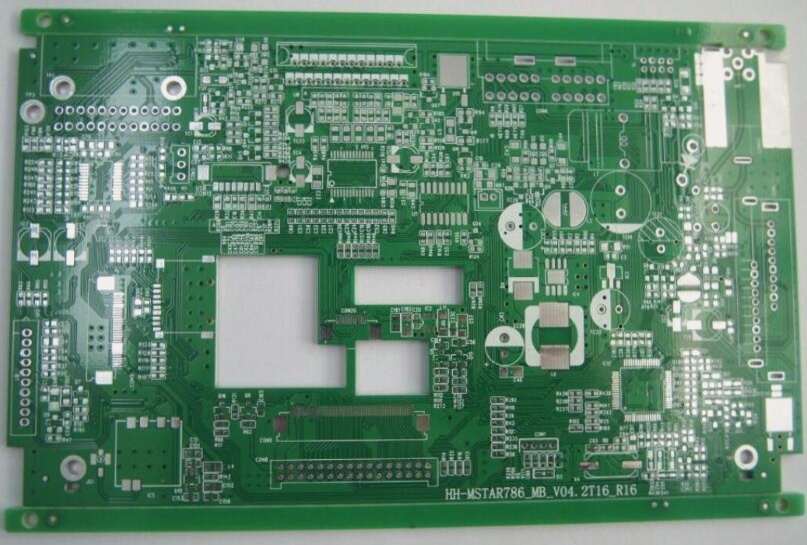

- 1. **Design:** The initial stage involves creating a layout design for the PCB, determining component placement and connection routes.

- 2. **Printing (Etching):** This step uses a chemical process to remove excess copper from the PCB, leaving behind the desired circuit pattern.

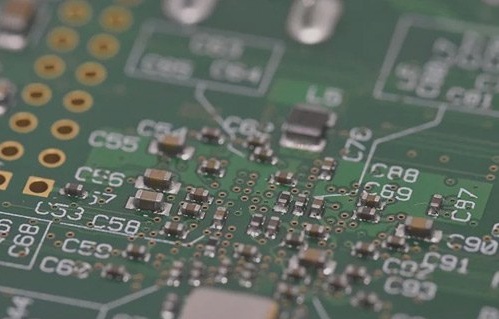

- 3. **Placement (Curing):** To ensure precise installation of surface-mount components, a placement machine is utilized after the printing process.

- 4. **Reflow Soldering:** By utilizing a reflow oven, the solder paste is melted to securely bond the surface-mounted components onto the PCB.

- 5. **Cleaning:** The final step involves eliminating any harmful solder residue from the assembled PCB, using a cleaning machine placed strategically as required.