How to Design the Characteristic Impedance

In high-speed PCB design, we often perform characteristic impedance control on high-speed signal lines to optimize signal quality. What is the characteristic impedance?

1. Transmission Line Principle

Before introducing the characteristic impedance, let’s review the basic principles of transmission lines covered in the “Signal Integrity Video.” As shown in the figure on the left, the low-frequency circuit uses the RLGC model with lumped parameters, while the high-frequency circuit on the right employs the RLGC model with distributed parameters.

Solving the transmission line calculus equation is straightforward for you, so I won’t elaborate on it here. The result of the equation enables us to determine the attenuation constant, characteristic impedance, phase shift constant, etc., of the PCB transmission line. The specific meanings are described in detail in the “Signal Integrity Video.” Here, we mainly focus on the application of PCB characteristic impedance. Below is the formula for the characteristic impedance derived from the equation, but it may not be very useful, as you cannot easily ascertain the values of R, L, G, and C corresponding to the unit length.

2. The Influence of Characteristic Impedance Mismatch

The characteristic impedance of the transmission line refers to the impedance experienced at each point along the line when high-speed signals traverse the PCB. It is crucial for the characteristic impedance of the transmission line to remain stable, as sudden changes will induce signal reflections that negatively impact signal quality.

3. Selection of Characteristic Impedance

The characteristic impedance of the PCB is determined by the load matching resistance ZL at the load end, which is influenced by the specifications of various interfaces. The characteristic impedance error is primarily affected by the PCB fabrication process and can generally be controlled within 5% to 10%. Below are common interface PCB impedance specifications.

USB differential cable: 90Ω

PCIE differential line: 100Ω

RF single-ended transmission line: 50Ω

Ordinary single-ended transmission line: 50Ω

4. PCB characteristic impedance design

Currently, PCB manufacturers often utilize Polar SI9000 software to calculate characteristic impedance. Let’s consider a single-ended signal line as an example, which involves four key parameters: dielectric constant, dielectric thickness, line width, and copper foil thickness.

Dielectric constant (Er1): This refers to the dielectric constant of the substrate, typically ranging from 4.2 to 4.5 for FR4 substrates.

Medium thickness (H1): This parameter denotes the thickness of the substrate or the prepreg.

Line width (W1/W2): This specifies the width of the PCB trace.

Copper foil thickness: Depending on specific requirements, options include 0.5 oz, 1 oz, 2 oz, etc.

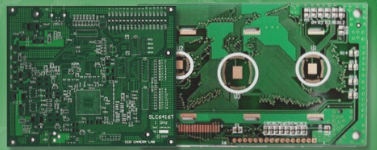

5. Wireless charging PCBA specifications

Supporting 5W/7.5W/10W/15W power adaptation; integrating a 32-bit high-performance processor; compliant with QI (BPPEPP) certification, conforming to the WPC1.2.4 protocol; incorporating a high-precision FOD algorithm; featuring integrated dual-channel fully synchronous digital demodulation; supporting OCP/OVP/OTP protections; compatible with QC2.0/QC3.0/AFC protocols; enabling DPL dynamic power adjustment; facilitating simultaneous charging of multiple devices; supporting customizable functions; and allowing USB upgrades.

Product features:

1. Single-chip 5W/10W transmitter solution.

2. Compatible with Type A6/A11/A28/MP-A2, etc.

3. WPC 1.2.4 certified.

4. Supports 10W fast charging protocol.

5. Achieves up to 85% efficiency for fast charging; 78% for.

6. Integrates synchronous dual-channel all-digital demodulation circuitry.

7. Provides over-temperature, over-voltage, dual over-current (software/hardware), and short-circuit protections.

8. Features FOD functionality.

9. Implements dynamic power lock.

10. Enhanced vertex shutdown capability.

11. Adapts to input voltages of 5V/9V.

12. Supports power sharing among multiple transmitters.

These products find extensive applications in:

– Smartphones and smart wearables

– Automotive electronics

– Medical devices

– Furniture and digital products

– Power banks

– Wireless charging platforms in home offices, airports, and restaurant chains, among other fields.

Cooperation models:

– Custom development of wireless charging technology solutions for various electronic products.

– Production and sale of wireless charger products and complete units.

– Distribution of wireless charging PCBA.

– Distribution of core MCUs for wireless charging authorization.

– Negotiation and cooperation with other parties.

Our advantages:

☑ Comprehensive inventory

☑ Professional services

☑ Authenticity guaranteed

☑ Efficient procurement processes

☑ Time-saving solutions

In high-speed PCB design, we often perform characteristic impedance control on high-speed signal lines to optimize signal quality. What is the characteristic impedance?

1. Transmission Line Principle

Before introducing the characteristic impedance, let’s review the basic principles of transmission lines covered in the “Signal Integrity Video.” As shown in the figure on the left, the low-frequency circuit uses the RLGC model with lumped parameters, while the high-frequency circuit on the right employs the RLGC model with distributed parameters.

Solving the transmission line calculus equation is straightforward for you, so I won’t elaborate on it here. The result of the equation enables us to determine the attenuation constant, characteristic impedance, phase shift constant, etc., of the PCB transmission line. The specific meanings are described in detail in the “Signal Integrity Video.” Here, we mainly focus on the application of PCB characteristic impedance. Below is the formula for the characteristic impedance derived from the equation, but it may not be very useful, as you cannot easily ascertain the values of R, L, G, and C corresponding to the unit length.

2. The Influence of Characteristic Impedance Mismatch

The characteristic impedance of the transmission line refers to the impedance experienced at each point along the line when high-speed signals traverse the PCB. It is crucial for the characteristic impedance of the transmission line to remain stable, as sudden changes will induce signal reflections that negatively impact signal quality.

3. Selection of Characteristic Impedance

The characteristic impedance of the PCB is determined by the load matching resistance ZL at the load end, which is influenced by the specifications of various interfaces. The characteristic impedance error is primarily affected by the PCB fabrication process and can generally be controlled within 5% to 10%. Below are common interface PCB impedance specifications.

USB differential cable: 90Ω

PCIE differential line: 100Ω

RF single-ended transmission line: 50Ω

Ordinary single-ended transmission line: 50Ω

4. PCB characteristic impedance design

Currently, PCB manufacturers often utilize Polar SI9000 software to calculate characteristic impedance. Let’s consider a single-ended signal line as an example, which involves four key parameters: dielectric constant, dielectric thickness, line width, and copper foil thickness.

Dielectric constant (Er1): This refers to the dielectric constant of the substrate, typically ranging from 4.2 to 4.5 for FR4 substrates.

Medium thickness (H1): This parameter denotes the thickness of the substrate or the prepreg.

Line width (W1/W2): This specifies the width of the PCB trace.

Copper foil thickness: Depending on specific requirements, options include 0.5 oz, 1 oz, 2 oz, etc.

5. Wireless charging PCBA specifications

Supporting 5W/7.5W/10W/15W power adaptation; integrating a 32-bit high-performance processor; compliant with QI (BPPEPP) certification, conforming to the WPC1.2.4 protocol; incorporating a high-precision FOD algorithm; featuring integrated dual-channel fully synchronous digital demodulation; supporting OCP/OVP/OTP protections; compatible with QC2.0/QC3.0/AFC protocols; enabling DPL dynamic power adjustment; facilitating simultaneous charging of multiple devices; supporting customizable functions; and allowing USB upgrades.

Product features:

1. Single-chip 5W/10W transmitter solution.

2. Compatible with Type A6/A11/A28/MP-A2, etc.

3. WPC 1.2.4 certified.

4. Supports 10W fast charging protocol.

5. Achieves up to 85% efficiency for fast charging; 78% for.

6. Integrates synchronous dual-channel all-digital demodulation circuitry.

7. Provides over-temperature, over-voltage, dual over-current (software/hardware), and short-circuit protections.

8. Features FOD functionality.

9. Implements dynamic power lock.

10. Enhanced vertex shutdown capability.

11. Adapts to input voltages of 5V/9V.

12. Supports power sharing among multiple transmitters.

These products find extensive applications in:

– Smartphones and smart wearables

– Automotive electronics

– Medical devices

– Furniture and digital products

– Power banks

– Wireless charging platforms in home offices, airports, and restaurant chains, among other fields.

Cooperation models:

– Custom development of wireless charging technology solutions for various electronic products.

– Production and sale of wireless charger products and complete units.

– Distribution of wireless charging PCBA.

– Distribution of core MCUs for wireless charging authorization.

– Negotiation and cooperation with other parties.

Our advantages:

☑ Comprehensive inventory

☑ Professional services

☑ Authenticity guaranteed

☑ Efficient procurement processes

☑ Time-saving solutions