Single-Sided Printed Circuit Boards in Consumer Electronics

- Single-sided printed circuit boards are commonly used in consumer electronics such as radios, tape recorders, televisions, and electronic game consoles.

- They offer low manufacturing costs compared to other types of printed boards.

- Single-sided PCBs are also suitable for industrial electronic products.

- These boards are ideal for circuits with low complexity and density, where all interconnections can be achieved on one side.

Double-Sided and Multilayer Printed Circuit Boards

- When complete interconnection is not possible with a single-sided PCB, consider using a double-sided PCB with metallized holes for through-connection.

- For more complex needs, multilayer PCBs are recommended, especially for high-speed circuits, improved reliability, and simplified layout.

- Flexible printed circuits or flexible-rigid printed circuits can be used for specific assembly requirements, weight reduction, and improved density.

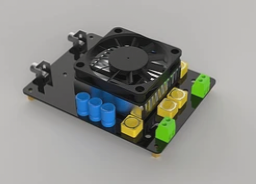

- Design incorporating a metal core or surface heat sink is necessary for handling large currents or high power consumption.

Coordinate Network System and Design Enlargement Ratio

- A coordinate network system is commonly used in PCB design for easy compilation and generation of control programs.

- The design enlargement ratio, such as 2:1 or 4:1, plays a crucial role in achieving dimensional accuracy in printed circuit boards.

- Using the national standard grid system simplifies calculations and operations in manual layout and photographic basemap production.

Production Conditions

When designing printed circuit boards, it’s crucial to consider production conditions. This involves understanding methods like photographic plate creation (e.g., photographic reduction, light drawing, 1:1 mapping), the allowable base image size for the photographic platesetter, board dimensions processed by machines, drilling machine precision, blanking needs, fine wire pattern printing, and etching accuracy.

Standardization

Standardization plays a key role in simplifying PCB production, reducing costs, shortening cycles, and ensuring quality. Designers need to follow relevant standards like National Standards (GB), International Electrotechnical Commission (IEC TC52), US Military Specifications (MIL), British Standards (BS), Japanese Industrial Standards (JIS), and Japan Printed Circuit Association (JPCA).

Design Documents

-

Circuit Diagram (Electrical Schematic Diagram)

Aside from standard circuit connection methods, the diagram should highlight special components based on design needs, like input/output relationships, key signal line lengths, ground-protected conductors, specific width conductors, EMI-generating devices, heat-producing components, and thermal elements.

-

Components Table

This list covers resistors, capacitors, transistors, diodes, ICs, transformers, inductors, heat sinks, and metal parts. It should detail circuit diagram references (e.g., R1, R2, C1, C2), component specs, metal part match requirements, mechanical dimensions, and possibly actual component samples.

-

Component Wiring Table

Used in CAD automatic routing, this table shows component connection relationships.

-

Machining Drawing

- a. Board dimensions and deviations, plug portions, mounting hole dimensions, and reference datum deviations.

- b. Details of copper clad laminate, like name, symbol, thickness, and copper foil thickness, with focus on insulating substrate thickness between foils.

- c. Surface coating technical specs, such as tin-lead coating thickness, ratio, nickel/gold coating thickness, etc.

- d. Requirements for surface coatings like solderability and solder mask coatings.

- e. Assembly drawings and component tables crucial for PCB electrical assembly.