What impact will lead-free soldering technology have on PCB circuit board components?

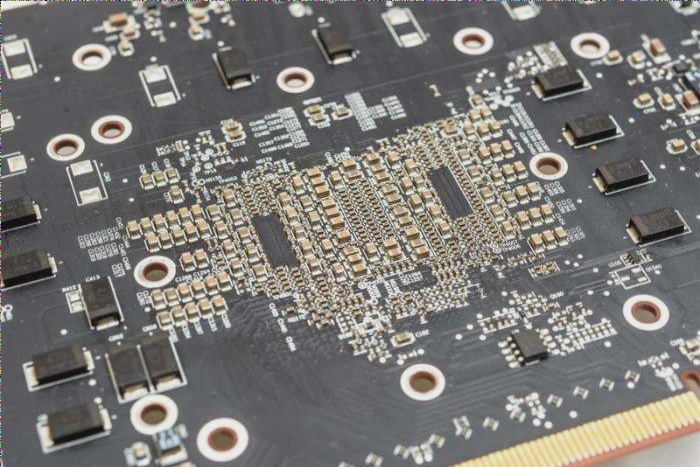

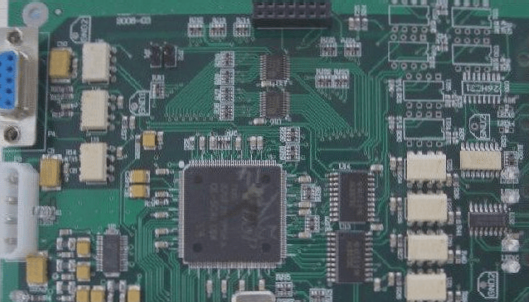

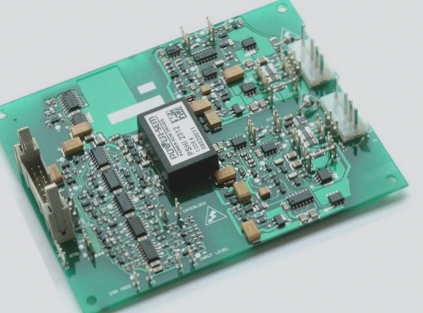

Generally speaking, PCB components with various electronic parts must undergo a soldering process during assembly. Wave soldering is a common and well-known method. When PCB components transition to lead-free wave soldering, they face several challenges. As with any new manufacturing technology, anticipated challenges are often pre-estimated and prepared for in advance.

However, some challenges may not be known until after mass production begins, revealing issues that only sufficient data can address. Thus, engineers often gain insights and learn from the production process over time.

In reality, lead-free assembly is not a novel process. Lead-free wave soldering has been practiced for many years. Prior to the RoHS regulations, electronic assembly engineers had already dealt with higher soldering temperatures due to the elevated melting point of the silver-tin solder used.

1. These electronic components are designed to withstand harsh environments, and because they are relatively uncomplicated, their performance is generally acceptable.

2. When RoHS regulations are introduced into mainstream electronic assembly, transitional early products, including consumer electronics, are relatively simple to adapt.

3. By using single-sided or double-sided PCB components, SMT devices that are less troublesome are utilized on the PCB soldering surface.

4. The transition to lead-free electronic components is generally smooth, requiring minimal changes to the process parameters originally set for tin-lead alloys.

5. In many cases, even basic solders suitable for tin-lead alloys can be successfully employed in lead-free process operations.

6. Through years of research, it has been found that using lead-free soldering with a 1.6mm thick PCB results in a slightly tighter process window.

7. The change in preheating requirements is not significant, and most current welding equipment can accommodate these changes.

8. Soldering temperatures may need to be increased, depending on the melting temperature of the previous tin-lead alloy process.

9. Completely filling holes with lead-free solder can present challenges, especially for products with OSP surface coatings.

10. Wave soldering pause times may be one second or more than two seconds, and lead-free alloys can be more challenging to manage in terms of drainage and bridging compared to tin-lead alloys, particularly for devices with fine pitch.

11. For less complex components, most challenges can be addressed by adjusting parameters and employing basic process control measurement techniques.

12. As thicker PCBs with more layers and complex electronic components, such as those in program-controlled switches, transition from tin-lead to lead-free soldering, the differences between tin-lead and lead-free process operations become more pronounced.

Generally speaking, PCB components with various electronic parts must undergo a soldering process during assembly. Wave soldering is a common and well-known method. When PCB components transition to lead-free wave soldering, they face several challenges. As with any new manufacturing technology, anticipated challenges are often pre-estimated and prepared for in advance.

However, some challenges may not be known until after mass production begins, revealing issues that only sufficient data can address. Thus, engineers often gain insights and learn from the production process over time.

In reality, lead-free assembly is not a novel process. Lead-free wave soldering has been practiced for many years. Prior to the RoHS regulations, electronic assembly engineers had already dealt with higher soldering temperatures due to the elevated melting point of the silver-tin solder used.

1. These electronic components are designed to withstand harsh environments, and because they are relatively uncomplicated, their performance is generally acceptable.

2. When RoHS regulations are introduced into mainstream electronic assembly, transitional early products, including consumer electronics, are relatively simple to adapt.

3. By using single-sided or double-sided PCB components, SMT devices that are less troublesome are utilized on the PCB soldering surface.

4. The transition to lead-free electronic components is generally smooth, requiring minimal changes to the process parameters originally set for tin-lead alloys.

5. In many cases, even basic solders suitable for tin-lead alloys can be successfully employed in lead-free process operations.

6. Through years of research, it has been found that using lead-free soldering with a 1.6mm thick PCB results in a slightly tighter process window.

7. The change in preheating requirements is not significant, and most current welding equipment can accommodate these changes.

8. Soldering temperatures may need to be increased, depending on the melting temperature of the previous tin-lead alloy process.

9. Completely filling holes with lead-free solder can present challenges, especially for products with OSP surface coatings.

10. Wave soldering pause times may be one second or more than two seconds, and lead-free alloys can be more challenging to manage in terms of drainage and bridging compared to tin-lead alloys, particularly for devices with fine pitch.

11. For less complex components, most challenges can be addressed by adjusting parameters and employing basic process control measurement techniques.

12. As thicker PCBs with more layers and complex electronic components, such as those in program-controlled switches, transition from tin-lead to lead-free soldering, the differences between tin-lead and lead-free process operations become more pronounced.