Legend Printing on Circuit Boards

Legend printing, also known as silkscreen printing, is a crucial process in PCB manufacturing. It involves adding text or patterns to the board’s surface, such as component references, part numbers, and company logos. Two primary methods are used: screen printing and Direct Legend Printing (DLP).

Screen Printing Method

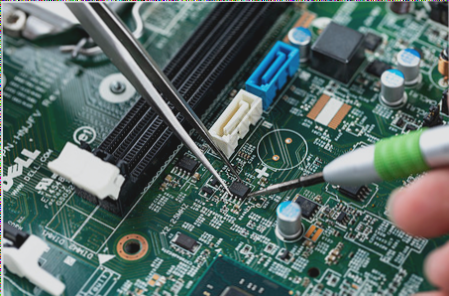

Screen printing utilizes a mesh screen to transfer ink onto the circuit board. A screen is created from a legend film, allowing ink to pass through graphic areas while blocking non-graphic areas. The board is then baked to secure the ink in place.

Direct Legend Printing (DLP)

DLP uses electronic inkjet technology to print information directly onto the board from CAD/CAM files. Special ink is cured with ultraviolet light for a precise and efficient printing process. DLP offers higher accuracy but is more suitable for small batches.

Importance of Legend Information

While legend printing is not essential for a board’s functionality, it aids in assembly and maintenance. Wellcircuits provides legends in black, white, yellow, or other colors as per customer specifications. The manufacturing standards ensure clear and readable characters on the board.

If you have any inquiries about PCBs or PCBA, contact us at info@wellcircuits.com.