1. PCB circuit board manufacturers can illustrate the differences between FPC and PCB. First, let’s explore the role of PCB:

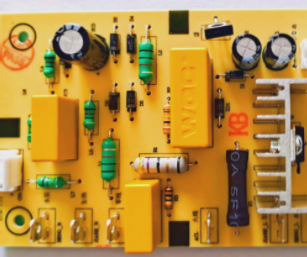

2. The Role of PCB: Once electronic equipment adopts printed circuit boards, the consistency among similar boards helps avoid manual wiring errors. This allows for automatic insertion or mounting of electronic components, automated soldering, and automatic detection, which enhances the quality of the equipment. This ultimately improves labor productivity, reduces costs, and simplifies maintenance.

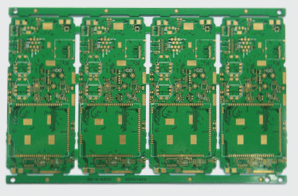

3. PCB Development: Printed boards have evolved from single-layer to double-sided, multi-layer, and flexible formats, each maintaining its own development trends. With ongoing advancements in precision, density, and reliability, and continual reductions in size and cost, printed circuit boards will remain vital in the future of electronic equipment.

4. Discussions on the future development trends of printed board manufacturing technology, both domestically and internationally, converge on several key points: high density, high precision, fine aperture, fine wire, fine pitch, high reliability, multilayer structures, high-speed transmission, lightweight designs, and thin types. Additionally, production must focus on increasing productivity, reducing costs and pollution, and accommodating multi-variety, small-batch production. The technical development level of printed circuits is generally represented by factors such as line width, aperture, and the plate thickness-to-aperture ratio.

### What is PCB?

1. PCB (Printed Circuit Board), known in Chinese as 印刷电路板 (printed circuit board), is a crucial component in the electronics industry.

2. Almost every type of electronic device, from electronic watches and calculators to computers, communication equipment, and military systems, relies on PCBs for the electrical interconnection of components such as integrated circuits.

3. In the development of larger electronic products, key success factors include the design, documentation, and manufacturing of the PCB.

4. The quality of PCB design and manufacturing directly impacts the overall product quality and cost, influencing commercial success or failure.

### What is FPC?

5. FPC (Flexible Printed Circuit) is a type of PCB, often referred to as “soft board”.

6. FPCs are made from flexible substrates like polyimide or polyester film and offer advantages such as high wiring density, light weight, thin profile, and exceptional flexibility.

7. They can withstand millions of dynamic bends without damaging the circuitry, allowing for movement and expansion according to spatial requirements, enabling three-dimensional assembly, and achieving integration of components and connections.

8. These advantages make FPCs unmatched by other circuit board types.

### Multilayer FPC Circuit Board Applications:

9. **Mobile Phones**: Emphasize the lightweight and thin nature of flexible circuits. They effectively reduce product size and integrate components like the battery, microphone, and buttons into a single unit.

10. **Computers and LCD Screens**: Utilize the integrated circuit design and thin profile of FPCs. Digital signals are converted into images displayed on LCD screens.

11. **CD Walkman**: Leverage the three-dimensional assembly and thinness of FPCs, turning bulky CDs into portable devices.

12. **Disk Drives**: Whether for hard disks or floppy disks, the high flexibility and ultra-thin 0.1mm thickness of FPCs are crucial for fast data reading in PCs and notebooks.

13. **Recent Uses**: Include components such as hard disk drive (HDD) suspension circuits and xe package boards.

### Future Development:

14. With the expansive FPC market in China, major companies from Japan, the United States, and Taiwan have established factories there.

15. By 2021, flexible circuit boards, like rigid ones, have seen significant advancement. However, FPCs are currently between the “climax” and “decline” phases of their product lifecycle.

16. To maintain market share and overcome this phase, FPCs must innovate continuously. Innovation is essential for breaking out of this cycle.

### Areas for Future Innovation:

17. **Thickness**: FPCs must become even thinner and more flexible.

18. **Bending Resistance**: Flexibility is a core feature of FPCs. Future FPCs need to be more bend-resistant, exceeding 10,000 bends, necessitating improved substrates.

19. **Price**: Currently, FPCs are significantly more expensive than traditional PCBs. Reducing costs could expand market reach.

20. **Craftsmanship Level**: To meet various requirements, FPC processes must advance, achieving finer apertures and more precise line widths and spacings.

21. By innovating and upgrading in these four areas, FPCs can experience a resurgence and a new phase of growth.

### Summary:

22. The consumer electronics market, driven by mobile devices like smartphones and tablets, has seen rapid growth with a clear trend toward miniaturization and thinning.

23. Traditional PCBs can no longer meet these evolving product demands, leading manufacturers to explore new technologies to replace them.

24. FPCs have emerged as a leading technology, becoming essential in electronic device components.

25. Additionally, the rise of wearable smart devices and drones has created new opportunities for FPC products, while the growing trend of display and touch controls has expanded FPC applications with small and medium-sized LCD and touch screens.

26. The latest reports suggest that flexible electronic technology will drive a trillion-scale market, presenting an opportunity for China to advance its electronics industry and potentially establish it as a national pillar industry.

2. The Role of PCB: Once electronic equipment adopts printed circuit boards, the consistency among similar boards helps avoid manual wiring errors. This allows for automatic insertion or mounting of electronic components, automated soldering, and automatic detection, which enhances the quality of the equipment. This ultimately improves labor productivity, reduces costs, and simplifies maintenance.

3. PCB Development: Printed boards have evolved from single-layer to double-sided, multi-layer, and flexible formats, each maintaining its own development trends. With ongoing advancements in precision, density, and reliability, and continual reductions in size and cost, printed circuit boards will remain vital in the future of electronic equipment.

4. Discussions on the future development trends of printed board manufacturing technology, both domestically and internationally, converge on several key points: high density, high precision, fine aperture, fine wire, fine pitch, high reliability, multilayer structures, high-speed transmission, lightweight designs, and thin types. Additionally, production must focus on increasing productivity, reducing costs and pollution, and accommodating multi-variety, small-batch production. The technical development level of printed circuits is generally represented by factors such as line width, aperture, and the plate thickness-to-aperture ratio.

### What is PCB?

1. PCB (Printed Circuit Board), known in Chinese as 印刷电路板 (printed circuit board), is a crucial component in the electronics industry.

2. Almost every type of electronic device, from electronic watches and calculators to computers, communication equipment, and military systems, relies on PCBs for the electrical interconnection of components such as integrated circuits.

3. In the development of larger electronic products, key success factors include the design, documentation, and manufacturing of the PCB.

4. The quality of PCB design and manufacturing directly impacts the overall product quality and cost, influencing commercial success or failure.

### What is FPC?

5. FPC (Flexible Printed Circuit) is a type of PCB, often referred to as “soft board”.

6. FPCs are made from flexible substrates like polyimide or polyester film and offer advantages such as high wiring density, light weight, thin profile, and exceptional flexibility.

7. They can withstand millions of dynamic bends without damaging the circuitry, allowing for movement and expansion according to spatial requirements, enabling three-dimensional assembly, and achieving integration of components and connections.

8. These advantages make FPCs unmatched by other circuit board types.

### Multilayer FPC Circuit Board Applications:

9. **Mobile Phones**: Emphasize the lightweight and thin nature of flexible circuits. They effectively reduce product size and integrate components like the battery, microphone, and buttons into a single unit.

10. **Computers and LCD Screens**: Utilize the integrated circuit design and thin profile of FPCs. Digital signals are converted into images displayed on LCD screens.

11. **CD Walkman**: Leverage the three-dimensional assembly and thinness of FPCs, turning bulky CDs into portable devices.

12. **Disk Drives**: Whether for hard disks or floppy disks, the high flexibility and ultra-thin 0.1mm thickness of FPCs are crucial for fast data reading in PCs and notebooks.

13. **Recent Uses**: Include components such as hard disk drive (HDD) suspension circuits and xe package boards.

### Future Development:

14. With the expansive FPC market in China, major companies from Japan, the United States, and Taiwan have established factories there.

15. By 2021, flexible circuit boards, like rigid ones, have seen significant advancement. However, FPCs are currently between the “climax” and “decline” phases of their product lifecycle.

16. To maintain market share and overcome this phase, FPCs must innovate continuously. Innovation is essential for breaking out of this cycle.

### Areas for Future Innovation:

17. **Thickness**: FPCs must become even thinner and more flexible.

18. **Bending Resistance**: Flexibility is a core feature of FPCs. Future FPCs need to be more bend-resistant, exceeding 10,000 bends, necessitating improved substrates.

19. **Price**: Currently, FPCs are significantly more expensive than traditional PCBs. Reducing costs could expand market reach.

20. **Craftsmanship Level**: To meet various requirements, FPC processes must advance, achieving finer apertures and more precise line widths and spacings.

21. By innovating and upgrading in these four areas, FPCs can experience a resurgence and a new phase of growth.

### Summary:

22. The consumer electronics market, driven by mobile devices like smartphones and tablets, has seen rapid growth with a clear trend toward miniaturization and thinning.

23. Traditional PCBs can no longer meet these evolving product demands, leading manufacturers to explore new technologies to replace them.

24. FPCs have emerged as a leading technology, becoming essential in electronic device components.

25. Additionally, the rise of wearable smart devices and drones has created new opportunities for FPC products, while the growing trend of display and touch controls has expanded FPC applications with small and medium-sized LCD and touch screens.

26. The latest reports suggest that flexible electronic technology will drive a trillion-scale market, presenting an opportunity for China to advance its electronics industry and potentially establish it as a national pillar industry.