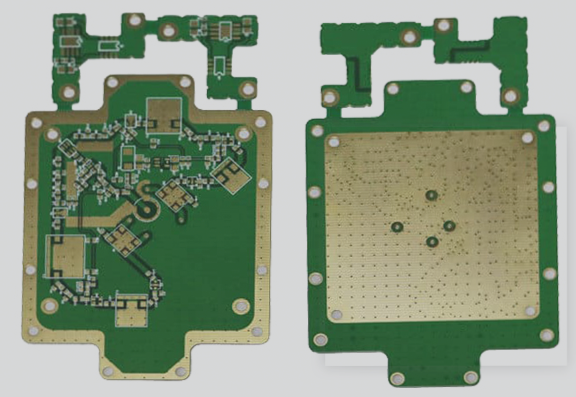

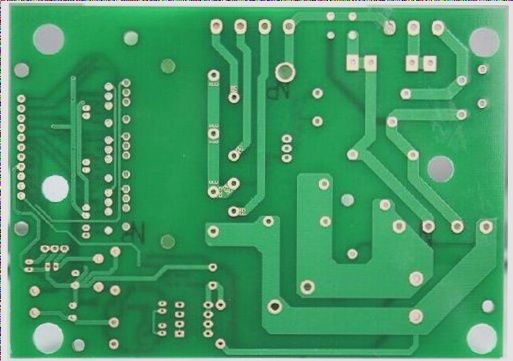

Common Causes of Poor Soldering in PCB Design

- Particulate impurities in the plating layer or grinding debris left on the circuit board surface.

- Contamination with grease, impurities, or residual silicone oil.

- Areas on the board surface lacking tin with particulate impurities in the plating layer.

- Rough high-potential coating, signs of burning, and areas without tin.

- Severely oxidized tin surface, dull copper surface in certain areas.

- Inconsistent plating between board sides, distinct bright edges around holes.

- Clear bright edges on low-potential holes, rough high-potential coating.

- Insufficient soldering temperature or time, improper flux usage.

- Inadequate tin plating coverage, dark red areas on the board surface.

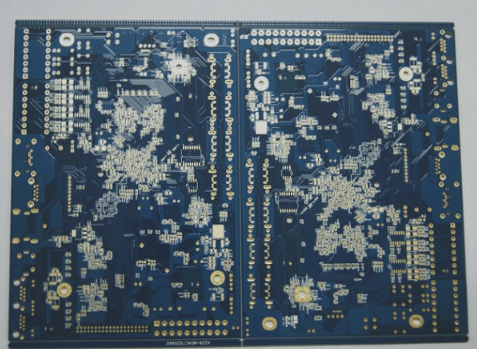

Causes of Poor Tinning on Circuit Boards

- Unbalanced bath composition, low current density, insufficient plating time.

- Inadequate number and uneven distribution of anodes.

- Low or excessive concentration of tinting agent.

- Large anode size, high current density, improper wire density in certain areas.

- Residual film or organic matter before plating.

- High current density, inadequately filtered plating solution.

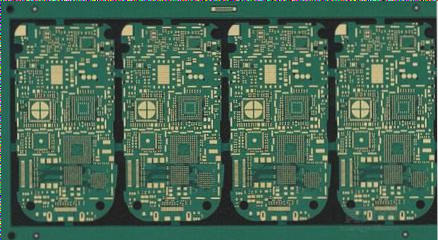

Strategies to Improve PCB Electro-Tinning Defects

- Regular chemical analyses and timely syrup composition adjustments.

- Periodic monitoring of anode consumption and adding anodes as needed.

- Hearst cell analysis for light agent adjustment.

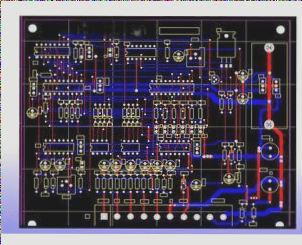

- Rational anode distribution, proper current density reduction, and wiring design.

- Enhanced pre-plating treatments.

- Reduced current density, regular maintenance of the filter system.

- Strict control of storage time and environmental conditions.

- Use of solvents for debris cleaning and specialized solvents for silicone oil.

- Precise temperature control during soldering (55-80°C) with sufficient preheating.

- Proper application of soldering flux.

Understanding and addressing these issues are crucial in the PCB industry to ensure high-quality soldering and tinning processes.