PCB Assembly: Tips for Cost-Effective Production

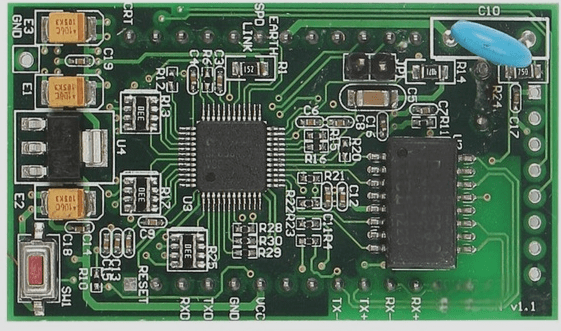

PCB assembly is the final stage where components are soldered onto a printed circuit board (PCB). The conductive pathways on the PCB, etched onto a copper sheet, are crucial for forming a functional component.

Low-Cost PCB Assembly Methods:

- Place Surface Mount Components On a Single Side: Opt for a single-sided PCB to reduce costs associated with mounting components on both sides.

- Properly Label Designators: Clear labeling simplifies placement, reducing manual costs.

- Panelize The PCB: Use panel formats for large-scale production to enhance efficiency and lower manufacturing costs.

- Minimize Board Size: Smaller PCBs can help cut down production expenses.

- Reasonable Component Placement: Maintain adequate spacing between components for better customization and heat distribution.

- Avoid Mixing Small and Large Parts: Simplify assembly by keeping similar components together.

- Minimize Through-Hole Parts Usage: Opt for surface-mounted devices to reduce manual labor and drilling costs.

Factors Impacting PCB Assembly Costs:

- Number of Layers: More layers increase costs, so aim for simpler designs.

- Size and Shape: Stick to common shapes to avoid additional expenses.

- Hole Size and Quantity: Larger holes and rings can help control costs.

- Complexity: Simplify designs to lower pricing and optimize component placement.

Reducing PCB production costs involves strategic decisions, such as choosing PCBs with fewer than 14 layers. By implementing these cost-effective tips, you can streamline the PCB assembly process and enhance overall efficiency.