Low-Speed Electric Vehicle PCB Copy Boards: A Growing Trend

Low-speed electric vehicle PCB copy boards are currently experiencing a resurgence, signaling a new era for these vehicles. Initially derived from golf carts, they were often viewed as “cottage cars.”

The Evolution of Copycat Manufacturing

- Low-speed electric vehicle PCB copy boards are now subject to increased regulation.

- China’s dual economic structure has provided a conducive environment for the growth of low-speed electric vehicles. The development of PCB copy boards mirrors the rapid adoption of smartphones in the country.

- Previously, unclear vehicle model definitions and technical standards led to a proliferation of copycat manufacturers. However, efforts to align with regulations and standards are driving these PCBs towards a more legitimate path.

Adaptation to Local Conditions

It’s essential for low-speed electric vehicle PCB copy boards to be customized according to local requirements.

Innovations in PCB Copy Board Development

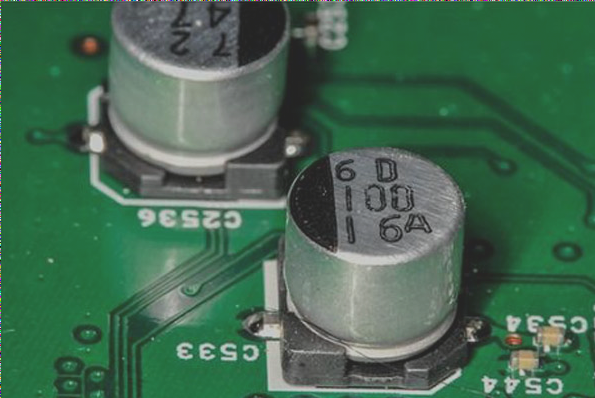

Creating a low-speed electric vehicle PCB copy board involves more than just replication. Manufacturers are now focusing on differentiation based on local characteristics and conditions. This includes modifying PCBs, software, and hardware functions to meet specific needs.

Ensuring Safety and Quality

Contrary to the belief that low speed equals low safety and low price equals poor quality, manufacturers are prioritizing safety and quality in the development of low-speed electric vehicle PCB copy boards. Companies like Core Valley Technology are dedicated to enhancing research and development efforts to ensure sustainable development of small electric vehicles.