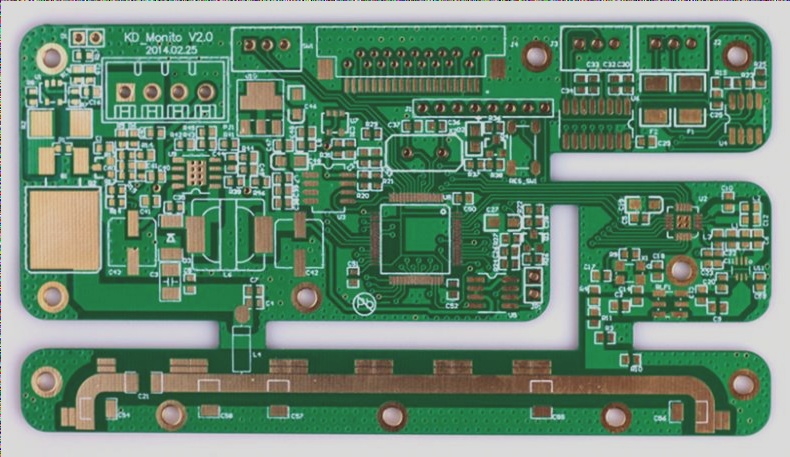

This is the era of technology and electronics. Every device we use today has a PCB, which goes through a long manufacturing process. Whenever the product development process is going on, the manufacturers often get the PCBs manufactured through different PCB manufacturing facilities.

When the product manufacturer is not dealing with the PCB manufacturing process, they must understand the difference between low volume and high volume PCB assembly. Understanding this difference makes it clear for the manufacturer if the production facility from the PCB manufacturer can handle the required production volume or not.

Well, there is much more to know about these two terms, so let’s explore why these are important and why you need to understand the difference.

What is Low Volume PCB Assembly?

Low volume PCB assembly is the circuit board’s most adaptable manufacturing and assembly process. Here the prototype circuit board is made, and its assembly design principles are followed to achieve top-notch and high-quality results. This type of PCB assembly is much more detailed because all three steps are done according to the requirements of the PCB, which are:

- Board Construction

- Component sourcing

- Board assembly

The manufacturing unit must be optimized for making this PCB to manufacture and assemble these boards. Along with the assembly line equipment, the procedure must also be synchronized according to the design of the PCB. Thus, this assembly method ensures better efficiency and quality when assembling PCB in a low volume. Low volume assembly adheres to DFMA principles. Thus, you get all the benefits of implying DFMA.

Usually, one batch only has around 250 PCBs when you select low-volume assembly.

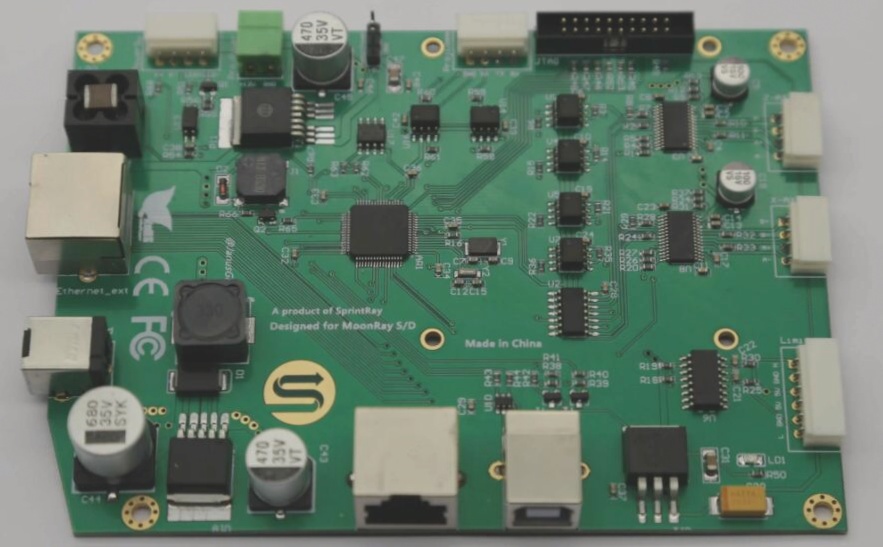

What is High Volume PCB Assembly?

When we talk about high-volume PCB assembly, it means that we require to manufacture PCBs in bulk. Thus, the minimum number of PCBs manufactured in one batch might be around 1000. The overall process can produce hundreds of thousands of PCBs per your requirements. High-volume PCB assembly needs a powerful and capable assembly method to meet the high-quality requirements. Some qualities of this method include:

- Consistency in the production process

- Homogeneity

- Automation production process

Due to these factors, this method of producing PCBs has many advantages, especially for organizations that mass produce electronic devices.

What is the difference between Low Volume PCB Assembly and High Volume PCB Assembly?

While the only major difference seems to be the assembly volume, many differences implement in the PCB quality and its features for your product. It mainly depends on which type you select for assembly volume. While there are many differences. The most important ones are discussed below.

Design creation

The first difference here is the design creation, which is also the first phase when manufacturing a PCB. When PCB is assembled in a high volume, the design will only be created once. It is because most of the features and components are standard. So, one design fits all through the prototyping process to production and deployment.

No matter how large the required volume is, only one design and prototype are created, and then it is followed for all the batches. Things are different for low-volume assembly. In that case, the batches have a small volume, so there is more room for customization, which allows for creating more designs.

Testing

The next difference here is testing. Testing is necessary for these assembly types, but their efficiency is different. In high-volume assembly, one prototype is created and tested. After it passes the result, the whole assembly production is tested according to the template for that prototype.

Testing is different for low-volume assembly because of the customization options and differences in design. Here every batch may have a different design to meet the specification requirements. Thus, a different prototype will be made and tested to ensure the correct functionality of the whole batch.

Time duration

Time duration is the next difference because it is important to deliver an effective PCB volume per the agreed time. In the case of High volume assembly, the time duration is shorter, which is to the benefit of both parties. It is because once you set the assembly line according to the requirements of the PCB, it can work consistently for making the PCB.

The time for prototyping, testing, designing, and component sourcing is also reduced. In this way, it may take a little time to start the assembly process, but once everything is set up, the time duration can be shortened significantly.

Attention to details

Attention to detail is in favor of the low volume assembly. It is because here, a less amount of PCB is going to be produced in one batch. So, if there is a design flaw in the production line, it will only be in that one batch of 250 PCBs. Any issue, in that case, may create loss, but that loss will not be that high.

On the other hand, high-volume PCB assembly needs attention to detail. First of all, the volume in one batch is higher. Secondly, if the flaw follows throughout the whole assembly production, it will bring significant losses. That’s why attention to detail here is extremely important.

Uniformity

One of the benefits of high-volume assembly is that there is production uniformity here. The output and features are the same across the production line, whether you need one batch or 100 batches of 1000 PCBs each. So, similar characteristics can be preserved. In the case of modularity being a feature of the PCB, it further helps.

Things are a little different in the case of Low volume assembly because of the differences and customizations. These PCBs can change after every batch. So, most of the characteristics cannot be preserved.

Cost and Budget

It is a general rule that things are cheaper when you manufacture or buy them in huge volumes. So, the high volume assembly is a benefit because bulk production and purchase significantly lower the cost and help you set a lower budget for the PCB in your product.

On the other hand, the low assembly volume can be costly. First, the resources involved in designing, customization, and testing, will increase the cost. Secondly, using dedicated components and different production principles will increase the cost. Lastly, these are not produced in bulk, so the prices are not lowered significantly.

Time to Market

Today faster time to market is necessary for every product that will hit the market. The product might get outdated if there is a long delay in hitting the market. High volume assembly has faster time-to-market capabilities because the OEMs are always fighting for market share. So, in this case, the tech and features can get to the market quickly.

The marketing and manufacturing process from the OEM helps a lot here because they are producing huge volumes of PCB at the same time. It may not be a benefit you get from the low-volume assembly. However, in some cases, both options can have a faster time to market depending on the circumstances.

Application of the PCBs

The last option is in the application of those PCBs. The low-volume assembly PCBs are often used in aircraft, automobiles, military, medical devices, and such industries. It is because every other device has a different feature and functionality. On the other hand, high volume assembly PCBs have many basic applications like LED circuits, calculators, etc.

Why understanding the difference between these two is important?

It is easier to understand how high-volume assembly is better for requirements where there is a high demand for units with conventional capabilities. On the other hand, the low volume PCB assembly is necessary for cases where a high volume of PCBs is not needed at once. Still, it is important to maintain unique features and functionalities.

Although all electronics may have a PCB, their feature and functionality requirements differ. It makes the PCB manufacturing requirements different as well. So, instead of looking for the pros and cons of each of these methods, you must understand the difference and go for the option that fulfills your requirements better. It is because each of these has different pros and cons. So, if you choose one of these assembly types without considering their specific characteristics, you will neither get the best quality PCBs nor the best e

Conclusion

A PCB works as a brain for electronic devices because all the digital calculations and operations are happening on the PCB. So, it is very important to get a PCB of the best quality that meets all the requirements of a product. When you get a PCB manufacturing factory to manufacture PCBs for you, it is important to consider the differences between low-volume PCB assembly and high-volume PCB assembly.

It is because these tell you how well that manufacturer can deal with your requirements. Thus, selecting the right manufacturer for the required volume of PCBs for your requirement will ensure that you get the best quality PCBs with the best experience.